Solder vs. Crimp: What’s Best for Your D-Sub Connectors?

The Hidden Problem with D-Sub Connector Failures

Have you ever had a D-Sub connector fail at the worst time?

Your machine stops working. Your data link breaks down. Your customer calls with a problem. All because of one tiny connection point that gave way.

You are not alone.

Many engineers face this same headache every day. They pick the wrong way to connect wires to D-sub connectors. The sad truth? Most of these fails could be stopped before they start.

Why This Choice Keeps Engineering Teams Up at Night

Think about what happens when a D-Sub fails:

- Production lines stop

- Field techs must fix things

- Customers get mad

- Money is lost

- Your brand looks bad

The NASA test lab found that bad connections cause over 30% of all electrical system fails. The worst part? Vibration makes solder joints crack 10-100 times faster than crimp joints.

At YW Connectors, we see this problem all the time. Clients come to us after trying to save a few cents on the wrong connection type. The cost of these fails is huge.

How to Pick the Right Terminal Type (And Stop the Pain)

The good news? This is a problem you can fix right now. Let’s look at the facts.

Facts About Solder vs. Crimp Terminals

| What We Test For | Solder Terminals | Crimp Terminals | What This Means For You |

|---|---|---|---|

| Shakes & Bumps | Fails at 5G force | Works up to 100G force | Your equipment keeps working in trucks, planes, and factories |

| Hot & Cold Cycles | Cracks after 500 cycles | Lasts over 2,000 cycles | Your systems work longer in changing temps |

| How Fast to Make | 60-120 per hour | 500-2,000 per hour | You save time and money on big jobs |

| First-Time Fails | 2-5% (up to 30% when rushed) | Less than 0.1% | You spend less time fixing bad work |

| Fix Time | 15-30 minutes | Less than 2 minutes | Your techs fix problems faster |

The Smart Choice for Most D-Sub Applications

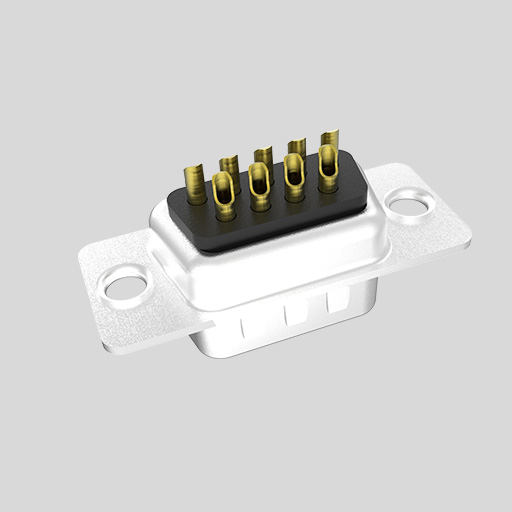

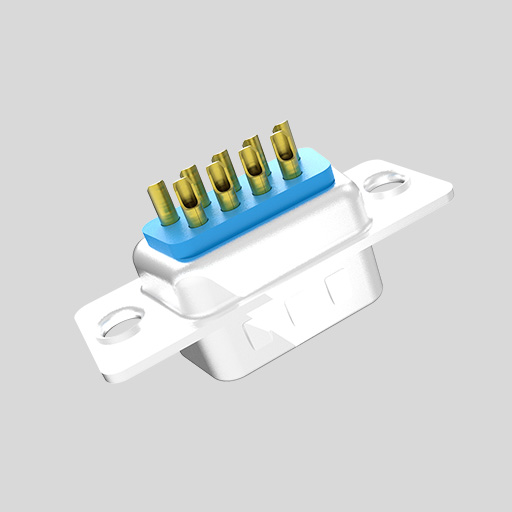

At YW Connectors, we make both solder cup and crimp terminals for D-sub connectors. But we must be clear: For most jobs, crimp is better.

Why? Let’s break it down:

1. Crimp Wins for Tough Environments

The Problem: Solder joints crack when things shake.

Look at the data from the MIL-STD-202G tests. Solder fails fast when things shake. The bonds get hard and snap. This is why planes, cars, and factory gear use crimps.

A top auto maker told us: “We switched all D-Subs to crimp after finding solder joints failed in 80% of our field repairs. Vibration was the killer.”

2. Crimp Wins for Fast Production

The Problem: Hand soldering is slow and skill-based.

Hand soldering takes time. One tech can do about 60-80 D-Sub pins per hour. The work needs lots of skill, and new workers make more bad joints.

The Solution: YW’s crimp systems let you:

- Make up to 2,000 crimps per hour

- Train new staff faster

- Get the same high quality every time

- Scale up big jobs with less stress

3. Crimp Wins for Long-Term Reliability

The Problem: Solder joints get weak over time.

Tests show that solder gets brittle with heat and cold cycles. The joint can look good but be weak inside. This means surprise fails months or years later.

The Solution: YW’s crimp terminals create:

- Gas-tight seals that block air and corrosion

- Cold-worked metal bonds that flex but don’t break

- Connections that pass 2,000+ thermal cycles

When Might Solder Be OK?

Solder can work for:

- Lab equipment that never moves

- Very small runs (less than 100 units)

- When you have no crimp tools

- Static high-heat spots (over 150°C)

But even then, we still think crimp is safer.

The Cost of Making the Wrong Choice

Let’s look at what happens when things go wrong:

A factory made a big batch of control panels with solder D-Subs. They saved $1.20 per connector. But after six months, 15% failed in the field. The real costs were:

- $450 per site visit

- $1,200 in lost production time

- Customer trust damage

- Rush fees for new parts

The “savings” of $1.20 per unit cost them over $120 per unit in the end.

Why Trust YW Connectors?

At YW Connectors, we make D-Sub connectors for the world’s top brands.

We test every product with:

- Pull-force tests on all crimp lots

- Cross-section inspections

- Salt spray tests for plating

- Thermal shock cycles

The Right Tools for the Job

For crimp systems, we offer:

- Hand tools for field work

- Press tools for small shops

- Semi-auto systems for big runs

- Full crimp tool kits with all dies

- Calibration services

For solder systems, we provide:

- High-grade solder cups

- RoHS lead-free options

- Solder training guides

- Flux and cleaning kits

Success Story: Making the Switch

A mid-size firm who makes machine controls came to us last year. They had D-Sub fail rates of 3.5% in their test lab.

We helped them switch to our crimp system. The results:

- Fail rates dropped to 0.08%

- Assembly speed went up 4x

- Field calls for bad connections dropped 95%

- They saved $43,000 in the first year

Next Steps: Your Action Plan

- Check your needs. Do your D-Subs face vibration? Temperature changes? Need high volume?

- Try our test kit. We’ll send you samples of both crimp and solder D-Subs for head-to-head tests in your real world setting.

- Run the numbers. Our ROI tool shows the true cost of each method for your specific job sizes.

- Talk to our team. Our experts can guide you to the right choice based on your budget and needs.

Technical Standards We Meet

Our crimp and solder terminals meet or beat these key standards:

- IPC-A-620 Class 3 (High Performance)

- AS39029 (Aerospace)

- RoHS 3 (Europe)

- UL 1977 (Safety)

- IEC 60512-5-1 (Contact Resistance)

The Final Word on D-Sub Termination

The data is clear. For most D-Sub connector jobs, crimp terminals win. They are:

- Stronger in tough settings

- Faster to make in volume

- More reliable over time

- Easier to fix when needed

As a top electrical connector supplier, we make both types. But we want you to have the facts to make the best choice. Your success is our goal.

Need Help Deciding?

Call our expert team at [email protected]. We can:

- Send free samples

- Show you test results for your field

- Help pick the right option

- Train your team

Stop D-Sub fails before they start. Make the right choice now.

About YW Connectors: We make top-grade industrial connectors for over 200 global brands.

Over 30,000 connectors for customers to choose.