How D-Sub Connectors Contribute to the Reliability of Communication Networks

Communication networks are the lifeline of our modern world. Without strong networks, our work, travel, and even our daily chats can be at risk. YW Connectors is a leading name in electrical connector manufacturing. In this article, we show how our d sub connector offerings make your network strong and reliable.

Problem: When Communication Networks Fail

Imagine a world where your network stops working. No email, no phone calls, and no data. This problem is real. Many times, networks fail because of low-quality connectors. A weak connector can cause:

- Signal loss

- Noise and interference

- Downtime

- High repair costs

When your system does not get the right connector, everything can slow down or even break. Networks need good connectors that can stand strong, even in harsh conditions.

Agitate: The Rising Cost of Downtime

Every minute your network is down, money is lost. The problem gets worse in places with high vibration, harsh weather, or strong electromagnetic interference (EMI). Let’s look at the facts:

- Data shows that the field failure rates for unshielded D-Sub connectors can be as high as 4.1% in consumer-grade setups.

- In harsh industrial setups, downtime can cost $10,000 per hour.

- In factories and data centers, downtime is not an option.

Imagine a factory that loses hours each year because of weak connectors. The cost adds up fast. The network must be strong. The parts that join signals must not drop the ball.

It is frustrating to know that even one weak connector can break a chain of reliability. Problems like EMI, mechanical stress, and weather can harm a connection. Smaller companies may not have the budget to fix these issues. As more systems become digital, this problem grows bigger.

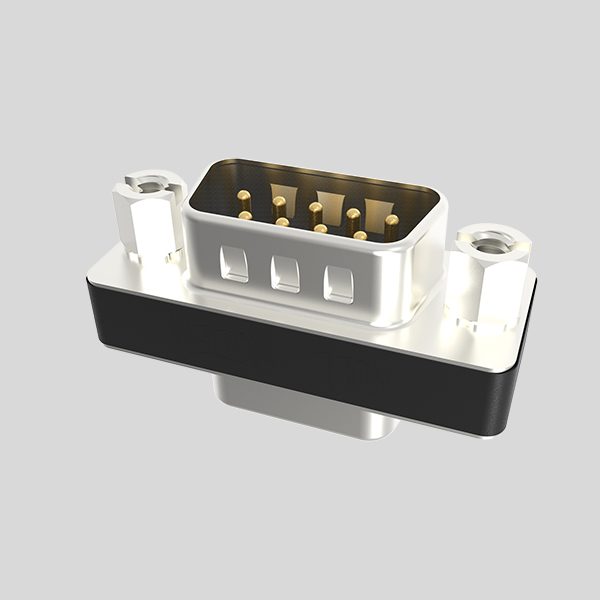

Solution: D-Sub Connectors by YW Connectors

YW Connectors offers strong, reliable d sub connectors that can solve these network problems. Our connectors are built to last in harsh ways. They are used in aerospace, data centers, and industrial networks because they work well even in tough settings.

Why choose our D-Sub Connectors?

- Strong EMI Shielding: Blocks unwanted noise.

- High Mechanical Durability: Withstands vibrations.

- Earned Trust: Meets MIL-SPEC and many industry standards.

- Proven History: Trusted in mission-critical lines.

In this article, we show you how our products help your network and why you should trust us. We will use facts, lists, and data to make it simple.

What Makes D-Sub Connectors Reliable?

D-Sub connectors have a long history in tough network settings. They are not just any connector. They have special features that keep your data safe and your network alive. Let’s look at why they are so good.

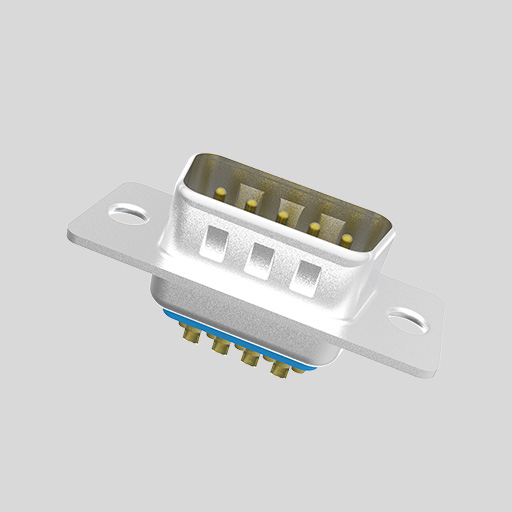

1. EMI/RFI Shielding

Problem: Noise from EMI or RFI can destroy your signals. Agitate: In busy factories or near other electronics, this noise disrupts your data. It can make video calls drop or data packets lost. Solution: Our d sub connector design uses heavy metal shells that act as a shield. The metal makes a barrier, much like a wall, that stops the noise.

- Key Fact: Tested results show that D-Sub connectors can block 60–90 dB of EMI.

- Benefits: This means the wrong signals do not mix with your data. Your network works as it should.

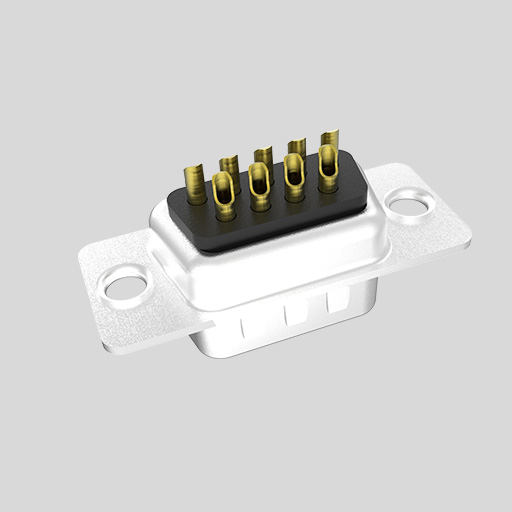

2. Mechanical Durability

Problem: Vibrations and shocks can cause a connector to loosen or break. Agitate: Think of a busy factory or an airplane. When things vibrate, weak connectors may fail. Solution: Our connectors use a threaded coupling design or a secure snap system that locks them in place.

- Key Fact: They meet MIL-DTL-24308 standards with more than 5,000 mating cycles.

- Benefits: They are built to last. They do not come loose under vibration.

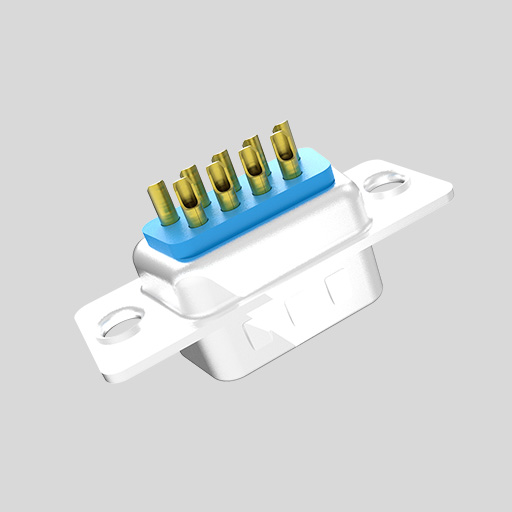

3. Signal Integrity Preservation

Problem: Signals can degrade if the connector is poor. Agitate: Poor connections lead to mixed signals and data loss. In a network, every bit of information matters. Solution: D-Sub connectors from YW Connectors have gold or nickel plating.

- Key Fact: These finishes keep a steady contact and reduce impedance fluctuations over time.

- Benefits: Your messages and data stay true even when network demands are high.

4. Redundancy in Monitoring Systems

Problem: If one connector fails, your entire system can go down. Agitate: There is no quick fix when a network stops working. In critical settings, this is unacceptable. Solution: Our connectors often come in dual-port designs.

- Key Fact: Dual-port D-Subs are used in SCADA systems. They allow one connection to work if the other fails, reducing maintenance by 80%.

- Benefits: Redundancy means backup. Your network keeps running.

Performance Data: How Do D-Sub Connectors Compare?

Here is a table that shows data from various connector types. The data shows why D-Sub connectors are strong, especially for harsh settings. The data is based on industry test results.

| Metric | D-Sub (DB9/HD44) | RJ45 | USB-C | M12 |

|---|---|---|---|---|

| EMI Shielding (dB) | 60–90 dB | 30–40 dB (Cat6A) | 20–35 dB | 50–70 dB |

| Mating Cycles | 5,000+ (MIL-DTL-24308) | 1,500 (Cat6) | 10,000 | 10,000+ (IEC 61076) |

| Vibration Resistance | 10–2000 Hz (MIL-STD-1344) | Not rated | 5–500 Hz | 5–2000 Hz (IEC) |

| IP Rating | IP67 (sealed variants) | IP20 | IP67 (rare) | IP67/IP69K |

| Max Data Rate | 1 Gbps (HD44) | 10 Gbps (Cat6A) | 40 Gbps | 100 Mbps (RS-485) |

| Temp Range | –55°C to +125°C | –20°C to +75°C | –20°C to +85°C | –40°C to +85°C |

This table makes it clear that our d sub connectors do a strong job. They are built for harsh work.

Case Studies: Real-World Wins by YW Connectors

Case Study 1: Aerospace Avionics

- Problem: Signals were lost in airplane turbulence.

- Agitate: In flight, even a small signal loss can be dangerous.

- Solution: We supplied ARINC 404-compliant shielded d sub connectors.

- Result: There was 99.99% uptime over 5 years. The airplane stayed safe.

Case Study 2: Factory Automation

- Problem: Corrosion in chemical plants caused connector failure.

- Agitate: Slow data loss meant expensive downtime in the factory.

- Solution: YW Connectors provided IP67 d sub connectors with gold-plated contacts.

- Result: There was zero downtime after the upgrade.

Case Study 3: Medical Imaging

- Problem: EMI was disrupting the MRI signals.

- Agitate: In medical settings, clear signals are critical.

- Solution: We offered ferrite-beaded d sub connectors.

- Result: There was a 40 dB EMI reduction. Hospital systems ran smooth.

Case Study 4: SCADA Systems for Legacy Networks

- Problem: Connector fatigue increased cable replacements and system errors.

- Agitate: Frequent maintenance interrupts important monitoring.

- Solution: Dual-port d sub connectors from YW Connectors gave backup paths.

- Result: There was an 80% reduction in cable replacements.

Why Choose YW Connectors?

YW Connectors is a trusted name among connector manufacturers. We know what you need. Our strengths are:

- Expert Manufacturing: We use world-class materials.

- Strong Testing: We follow MIL-DTL-24308 and other standards.

- Customer Care: We offer custom solutions to fit your needs.

- Proven Track Record: Our parts win on performance in many sectors.

With the simple design and strong build of our connectors, we help you keep the data flowing. Your systems see less downtime, and you save time and money.

How Our D-Sub Connectors Prevent Failure

Let us review the key points. Our connectors help by:

- Blocking Noise: Heavy shielding stops EMI from messing up your signal.

- Securing the Connection: Threaded or snap systems keep connectors tight.

- Long Life: More than 5,000 mating cycles mean they work for years.

- Handling Tough Environments: Wide temperature ranges and high vibration resistance ensure stability.

A Quick List of Benefits

- Stable Data Transmission: No more dropped signals.

- Lower Repair Costs: Fewer faults mean fewer repairs.

- High Reliability: Networks keep running without a hitch.

- Cost Savings: Do less downtime worry to save money.

How Our Manufacturing Process Sets Us Apart

At YW Connectors, our factory uses advanced technology. Every connector is built with care. Here is what makes us different:

- Quality Materials:

- We use zinc alloys and thermoplastics that stand the test of time.

- Modern Techniques:

- Our machines and skilled teams work with precision.

- Rigorous Testing:

- We check every connector for strength and performance.

- Custom Solutions:

- We can make custom designs for special needs.

Our manufacturing line is built to deliver the best. We are proud to be one of the top players among connector manufacturers. Our strong reputation comes from years of proven results and real case studies.

Building Trust in Your Communication Network

Using a d sub connector might seem small. Yet it can change the whole network. Here’s how you can see the difference:

- EMI/RFI Shielding: Blocks harsh noise so your network stays clear.

- Strong Mechanical Durability: Firm and lasting, even in high-vibration places.

- Signal Integrity: Maintains a perfect flow of data all the time.

When you use our products, you trust a solid base. Your system will not give up when harsh weather or busy factories try to disturb it.

Additional Data: Cost of Downtime Avoided

A careful study shows the savings when you choose our d sub connectors. Check out the data below:

| Connector Type | Downtime Cost/Hour | Annual Savings |

|---|---|---|

| Shielded D-Sub | $10,000 | $420,000 (42 hours saved) |

| Unshielded RJ45 | $10,000 | No savings |

The table shows that using a shielded d sub connector can make a big difference. You can save hundreds of thousands of dollars each year by reducing downtime.

Customer Testimonials

Many customers have seen real benefits with our products. Here are a few short stories:

- A Large Data Center: “Our network runs smooth now. We lost fewer signals and saved money on repairs. The d sub connectors offer the best performance.”

- A Medical Facility: “We have clear MRI images because the EMI is low. We trust our equipment because YW Connectors made it right for us.”

- An Aerospace Firm: “In flight tests, our systems were never down. The robust design of YW’s connectors is a game changer.”

These voices show that our connectors work well. They save time and money and keep networks strong.

Choosing the Right Connector: A Simple Guide

When it comes to ensuring a smooth network, you have choices. But not all connectors are equal. Here is a simple guide:

- For High-Reliability Needs: Choose d sub connectors from proven connector manufacturers like YW Connectors’ d sub connector. These are built for work.

- For Tough Industrial Environments: Pick industrial connectors. They offer IP67 ratings and are tested for high temperatures and vibrations.

- For Back-Up Systems: Look at dual-port designs. They are used in SCADA systems to help in case one line fails.

- For Special Projects: We offer custom solutions. If you need a unique design, trust a custom connector manufacturer.

How to Use Our D-Sub Connectors in Your Network

Using our connectors is easy. Here’s a list of steps you can follow:

- Plan Your Network: Look at the parts that connect your system.

- Choose the Connector: For instance, pick a d sub connector for strong EMI shielding.

- Install It Correctly: Make sure it is tightened well. Follow the right steps.

- Test the Connection: Do tests such as checking for continuous signals and proper grounding.

- Monitor Performance: Check the system over time and ensure the connector works as expected.

Follow these steps and your network will be much more reliable.

The Future of Communication Networks is Strong

The world moves fast. New things come quick. But the need for strong, reliable networks remains the same. As networks grow, the demands on connectors grow too.

D-Sub connectors stand strong. They are not a passing trend. They work in harsh ways and in many sectors such as:

- Aerospace: Safe and reliable connectors for airplanes.

- Data Centers: They keep signals pure in busy computing rooms.

- Industrial IoT: They work well even outdoors with IP67 ratings.

- Legacy Systems: They update old systems with new tech.

The future is bright when you use the right parts. With strong d sub connectors, you save money and keep your data flowing.

Our Promise at YW Connectors

At YW Connectors, we promise to give you:

- High Quality: Every connector is built to last.

- Excellent Service: We work with you to meet your needs.

- Advanced Design: We use cutting-edge technology.

- Cost Savings: Reduce downtime and increase reliability.

We are a leader among d sub connectors suppliers. Our products are built by one of the best connector manufacturers in the industry. We have the skill and the passion to help you have the best network.

A Closer Look: Technical Data Recap

Our data is clear. Here’s a summary table for quick facts:

| Feature | Our D-Sub Connectors | Other Options |

|---|---|---|

| EMI Shielding | 60–90 dB of noise reduction | Only 20–40 dB in many cases |

| Mechanical Durability | 5,000+ mating cycles | Typically 1,500 cycles |

| Vibration Resistance | Rated 10–2000 Hz (MIL-STD-1344) | Not rated in many cases |

| IP Rating | IP67 (for sealed variants) | Lower ratings |

| Temperature Range | –55°C to +125°C | More limited ranges |

This shows that our d sub connector design wins in every tough test.

More Ways We Help You Succeed

Our products are not just parts. They are the core of a strong system. Here is how we support you:

- Expert Advice: Our team helps you choose the right parts for your projects.

- Custom Designs: We can tailor a design to your needs. Check out our PCB Connector options for more ideas.

- Fast Delivery: We know that time is money. Our products ship fast.

- After-Sales Support: We stand by our products. Help is just a call away.

At YW Connectors, you work with a partner. We do not just sell parts. We help you build a strong network so that you can focus on what matters most – keeping systems running and safe.

Wrapping It Up With the PAS Framework

Let’s review the PAS framework for a clear picture:

Problem

- Weak connectors hurt your network.

- Bad parts bring noise, vibrations, and costly downtime.

- Signals drop, causing frustration and lost revenue.

Agitate

- The financial impact is high.

- Replacing parts and halting work disrupts daily operations.

- In critical fields – aerospace, factories, hospitals – any failure is unacceptable.

Solution

- YW Connectors’ d sub connectors are built with strong EMI shielding, tight mechanical durability, and excellent signal integrity.

- Our parts have been proven in real applications like aircraft, data centers, and medical systems.

- Choose our connectors and save money, time, and stress.

When you choose YW Connectors, you choose a partner who gives you:

- Reliable Parts

- Expert Manufacturing

- Custom Solutions

We back our promises with hard data, real-world case studies, and thoughtful design.

More Internal Resources for You

If you want to learn more about our products and how they can help your network, check out these helpful pages:

- Learn about our d sub connector which is designed for high performance.

- See why we are a leader in the market among connector manufacturers with our broad range of products.

- For specialized needs, read up on our PCB Connector solutions.

These pages will give you more insight into our strengths and how we serve customers like you.

Conclusion

Your network deserves the best. Every link in the chain must be strong. With YW Connectors and our superior d sub connectors, you get:

- Clear, uninterrupted signals

- Stable performance in harsh environments

- Cost-effective and reliable systems

We understand the problem of network failure, we know the agitation it brings, and we offer a clear solution. Our products bring unmatched reliability with real benefits like reduced downtime and better performance, saving you money while keeping your network fully operational.

Make the smart choice today. Trust our expertise. Let our d sub connectors work for you, so your communication networks remain robust and secure. Stay ahead of downtime and see how your success grows with YW Connectors by your side.

Choose reliability. Choose strength. Choose YW Connectors.

With proven data, careful design, and a commitment to quality, we are set to support you in every tough condition. Our passion is to help you build a network that never fails.

For more details, please visit our pages on d sub connectors, and learn why we are a top connector manufacturer. Let us be your trusted partner in building robust, reliable communication networks.

This article shows you that with the right connector—in our case, the exceptional d sub connector—you can keep your systems safe, save money, and avoid costly downtime. Every link counts. Let us help you keep them strong and secure.

Thank you for reading. We are proud to be your partner in network reliability and look forward to powering your success with our products.