Different Types of Connectors: Uses and Applications

INTRODUCTION

Electronic products have never been so varied. We put smart sensors on cow collars, diagnostic modules on aircraft wings, and lidar engines on driverless cars. Despite the distance between these fields, every design depends on a reliable, repeatable interconnect. A connector does more than complete a circuit. It speeds manufacturing, shields fragile silicon, and allows easy service. Pick a poor mate and you invite noise, heat, and expensive recalls. Pick the right one and your system ships faster, lasts longer, and earns a reputation for quality.

This article guide explains every major connector family, highlights critical specifications, and illustrates how real projects apply the technology. It pays close attention to circular connectors and to that rugged multitool—the d sub connector. The writing favors active voice, clear structure, and short sentences so you can act on the advice.

CONNECTOR FUNDAMENTALS

A connector is a system, not a single part. The shell defines mechanical strength and blocks electromagnetic interference. The insulator keeps contacts aligned under temperature swing and vibration. The retention mechanism—thread, latch, bayonet, or push‑pull—locks both halves together.

Designers choose stainless steel for seawater resistance, aluminum for low weight, and high‑performance thermoplastics when they need dielectric strength at a tight budget. Plating also matters. Nickel fights corrosion and accepts paint; tin splits cost on consumer gear; hard gold prevents fretting on low‑level signals.

CONTACT STYLES

Contacts carry current, wipe away oxide, and survive thousands of connections. Stamped‑and‑formed contacts dominate consumer and office equipment. Rollers cut them from continuous strip and fold them into shape in milliseconds. The method yields low cost and supports automatic crimping at ten thousand units per hour.

Machined contacts start as brass or copper alloy rod. A Swiss‑type lathe turns each dimension. The result is a concentric pin with controlled grain flow. You gain lower resistance, tighter tolerances, and longer mechanical life.

TERMINATION TECHNIQUES

Termination quality often drives system reliability. Four core methods exist, each with strengths and limits.

Crimp termination.

You strip the conductor, insert it into the rear barrel, and compress with a calibrated tool. Correct crimp geometry creates gas‑tight contact that resists corrosion and vibration. Automotive harnesses rely heavily on crimp because technicians can test pull‑out force in a second.

Solder termination.

Solder cups and through‑hole tails accept tin‑lead or lead‑free alloys. Solder works well for prototypes since you can hand‑assemble small runs with modest tools.

Insulation displacement (IDC).

Imagine pushing a ribbon cable against twin blades. The plastic yields, metal bites the copper, and an electrical path appears with no stripping or twisting. IDC suits digital signals below one ampere.

Screw clamp.

Field technicians love screw clamps. They carry a short screwdriver, loosen the captive screw, insert wire, and tighten to torque.

Press‑Fit Termination.

Modern backplanes often use compliant pins rather than solder. The pin has a slotted eye that flexes as it slides into a plated through‑hole. Once seated, the pin exerts continuous outward pressure, creating a gas‑tight joint without heat.

Wire‑Wrap Termination.

Vintage but not obsolete, wire‑wrap involves thin insulated wire wound around a square post. Each turn cold‑welds metal against metal. The method brings outstanding reliability and is still used in ultrahigh‑vacuum research.

SELECTING THE BEST CONNECTOR: ESSENTIAL SPECS

Operating temperature.

Check both ends. A connector that works at 120 °C may fail at −40 °C because seals stiffen and plating micro‑cracks. Always read charts that show continuous and short‑term limits.

Contact count.

More pins mean more functions, but also greater assembly time. Each extra pin adds roughly two seconds in manual crimp lines. It also raises mating force.

Mating cycles.

Wear is real. A gold flash may survive 50 insertions. Thirty micro‑meters of hard gold can last 1 000 or more.

Current and voltage rating.

Current heats the contact; voltage stresses the dielectric. Derate both for altitude because thin air cools poorly and ionizes sooner.

Contact resistance.

Target a few milliohms at low level. Measure at 20 mV, 10 mA to avoid self‑heating.

Insertion and extraction force. Multiply the per‑pin figure by total pins. If the result exceeds 75 N, installers will need tools or jackscrews.

Pitch.

Smaller pitch packs more pins but narrows creepage.

Ingress Protection.

Dust kills optical sensors, and water kills almost everything else. At IP67, you can dunk the mated pair for thirty minutes at one‑meter depth.

Mechanical arrangement.

Keying prevents human error.

Standards.

IEC 61076 covers metric circular connectors. MIL‑DTL‑24308 governs military D‑subs.

Thermal Rise Calculations. Use the classic I²R law to estimate self‑heating.

Altitude Derating Example. Atmospheric pressure halves every 5 500 m.

Vibration Metrics. Engineers quantify vibration by power spectral density (PSD) measured in G²/Hz.

CATEGORIES OF CONNECTORS

Metric Circular Connectors

The rise of Industry 4.0 pushed the humble M12 into spot‑light. Factories need Ethernet at the robot wrist, power to valve islands, and analog feedback from long conveyor belts.

M8 provides the same toughness in a smaller body for sensors and compact controllers. M5 shrinks size even further and fits tiny instruments.

Push‑Pull Circular Connectors

Push‑pull latching began in medical scopes sixty years ago. Today you find it in studio cameras, geophysical sensors, and battery swaps for racing drones.

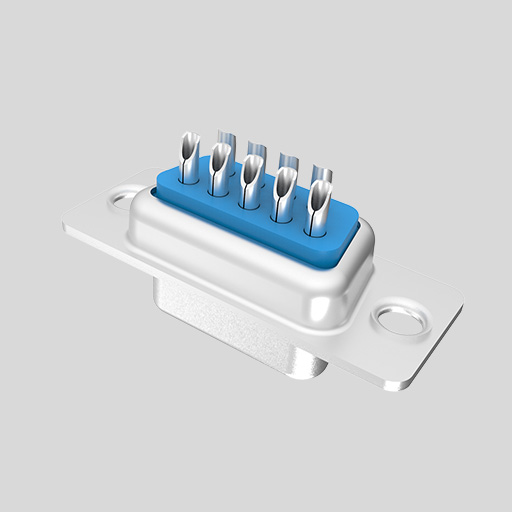

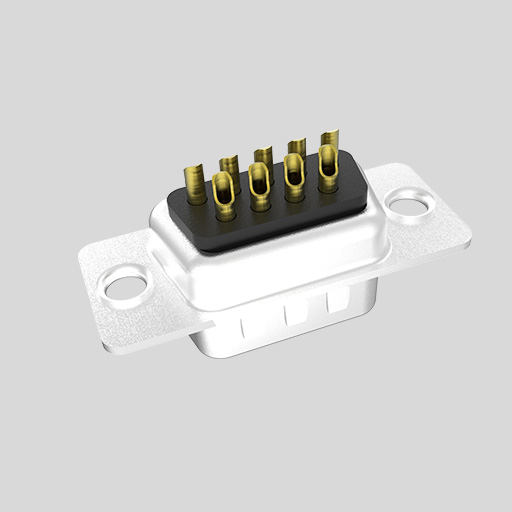

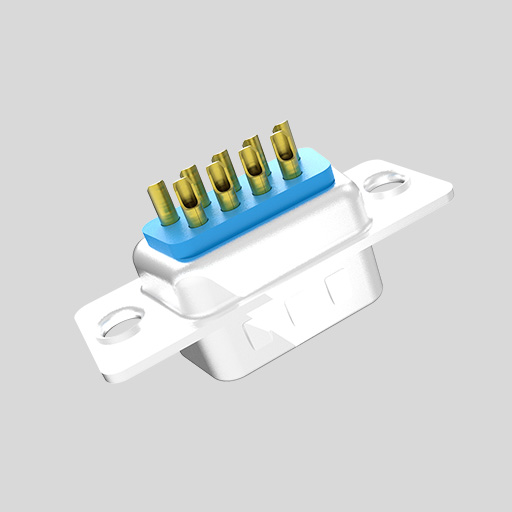

D‑Sub Connectors

The trapezoidal outline is older than the personal computer yet still evolves. A modern d sub connector can include machined contacts, right‑angle press‑fit tails, and rear gaskets.

Micro‑D Connectors

Micro‑D shrinks everything except performance.

IP‑Rated D‑Sub

Outdoor electronics used to rely on circular MIL connectors alone. Sealed D‑subs changed the game by offering familiar geometry with new gaskets.

Backshells and Hoods

You should never underestimate a backshell. It guides cable exit, clamps braid, and protects delicate solder joints.

Power‑D and Combo‑D

Mixed layouts shine when you must pass 24 V DC at 20 A next to 250 kb/s CAN.

Coaxial D‑Sub

Instrumentation racks thrive on coaxial D‑subs.

Custom Solutions

Sometimes catalog parts fall short.

Heavy‑Duty Rectangular Connectors

Although circular connectors rule tight spaces, heavy‑duty rectangular modules dominate machinery control cabinets because they stack neatly in gland plates.

APPLICATION FOCUS

Communications

Routers and base‑stations pump terabits while sitting on windy towers.

Industrial Automation

A car plant never sleeps. Inductive weld currents leap to 100 kHz and fling sparks metres away.

Medical Devices

Surgeons move fast; connectors must move with them.

Military and Aerospace

F‑35 flight computers see −55 °C on take‑off and 85 °C near avionics bays.

Robotics Cobots share space with humans and need sleek contours.

Rugged Environment Certification

Mining trucks bounce over washboard roads and dive headfirst into dust clouds.

Telematics Fleet operators demand 99.9 % uptime.

Test and Measurement Labs change setups hourly.

Transportation Rail OEMs fight sulphur fog, 105 °C roof temperatures, and 5 kV surges on brake valve lines.

IoT Edge Devices

Smart agriculture, smart street lighting, and home automation all rely on compact edge controllers that must live outdoors for a decade.

Space Exploration

Orbit and deep‑space projects stretch connectors to absolute limits.

EMERGING TRENDS IN CONNECTOR DESIGN

Signal speed doubles every few product generations.

SUSTAINABILITY AND REGULATORY COMPLIANCE

Carbon audits started in consumer devices; they now reach heavy equipment.

Green Manufacturing Practices. Forward‑looking factories run closed‑loop plating baths to recover copper and nickel, cutting metal discharge by 95 %.

CONCLUSION

Connectors look small, but they dictate the lifespan and serviceability of every electronic system.

Final Tip. Prototype early. Nothing replaces a bench test where you mate and unmate the plug a hundred times, dunk it in salt water, bake it overnight, and check resistance again.