How to choose the appropriate circular connector for your project

Circular connectors are one of the most types of electrical connectors used in industrial, medical, transport and automation applications. Its robust design, a compact and versatility factor make them ideal for hard environments and demanding tasks. However, choosing the appropriate circular connector for your project is not always simple. There are several parameters to consider, from the size and pin configuration to environmental classifications and blocking mechanisms.

In this article, we will break down the key aspects of circular connectors, we will provide practical selection tips and explore how they offer real world solutions in different industries.

Why circular connectors?

Before immersing themselves in the selection criteria, it is important to understand why circular connectors are often the first option in resistant and critical systems.

Advantages of circular connectors

Durability: Circular connectors are often designed with resistant shells made of high -grade plastic. This makes them suitable for environments where the shock, vibration, humidity and dust are common.

Ease of mating: Thanks to its round shape and ergonomic design, circular connectors are easier to align and mate than rectangular, especially in blind mating applications.

Sealing options: Most circular connectors are sealing with IP classification, protecting against water and dust entrance. This is vital for outdoor and industrial use.

Flexible configurations: They can be customized with different pins counts, signal types (power, data, RF) and blocking mechanisms, such as bayonet, threaded or pulled or pull-pull systems.

Standardization: Circular connectors often follow international standards (such as Mil-DTL-5015, M12 or M8), which guarantees compatibility and simplifies the supply.

Due to these benefits, circular connectors have become a reference solution for engineers who work in fields such as automation, robotics, aerospace and medical devices.

Key considerations when choosing a circular connector

Selecting the right circular connector requires more than just verifying the pins count. These are the most important criteria to evaluate:

- Electrical requirements

Start defining your current voltage and needs. Power connectors generally require larger contacts and greater insulation resistance, while signal connectors must handle the reduction and noise armor.

Current qualification: Make sure each contact can handle the expected current without overheating.

Voltage classification: Consider both work voltage and dielectric resistance voltage.

Signal integrity: for data or communication lines, shielding and impedance coincidence are crucial.

- Counting and design of pins

Determine how many circuits (or signals) must pass through the connector. In addition, consider whether you need mixed signal and power contacts within a single housing. Some circular connectors offer hybrid designs to accommodate this.

Standard configurations: Common Pin counts include 3, 4, 5, 8, 12 and more, depending on the series.

Personalized arrangements: Manufacturers often offer customizable insertions and coding to avoid mismatch.

- Environmental conditions

Circular connectors are often used in hostile environments. Verify the following qualifications:

IP rating: for water and dust resistance (for example, IP67 for waterproofing).

Temperature range: Make sure the connector is made under the thermal conditions of its application.

Vibration and shock: Use military degree connectors or industrial classification if mechanical stress is high.

- Blocking mechanism

The type of blocking system affects both reliability and ease of use:

Threaded connectors are safe but slower to mate. Bayonet locks offer a faster and faster connection.The Push-Pull systems allow rapid release and are often used in medical or audiovisual equipment.

Choose a blocking mechanism based on the frequency with which the connector will be coupled and does not compare, and the operational environment.

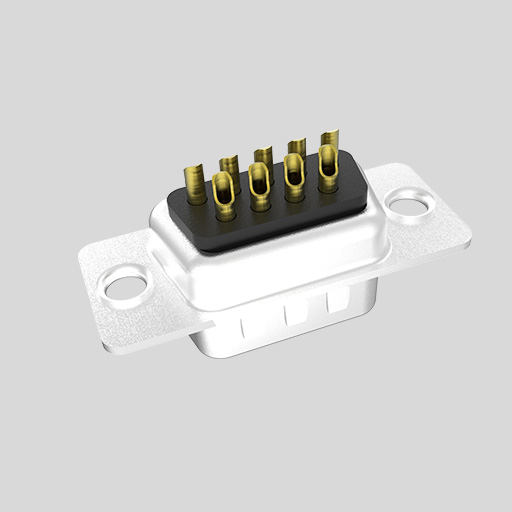

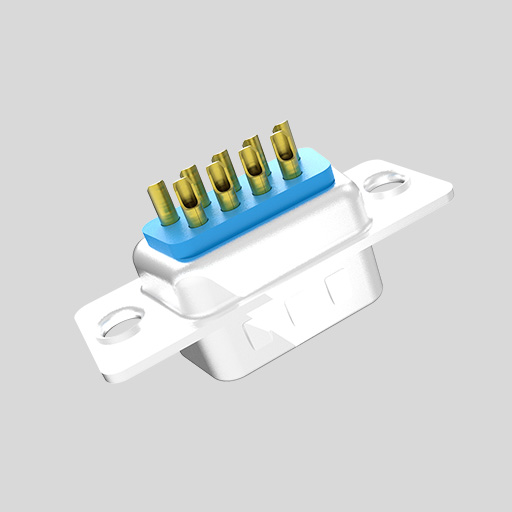

- Materials and veneered

The connector yield depends largely on the materials used both in the housing and in contacts.

Concha material: aluminum, stainless steel or plastic depending on the weight and corrosion resistance needs.

The contact veneer: the gold coating guarantees better conductivity and corrosion resistance, especially in data applications.

Common circular connector series and its applications

Understanding the types of popular circular connector can help you reduce your options more efficiently.

M12 and M8 connectors

Widely used in automation and sensor technology. These connectors are compact, classified by IP and ideal for the communication of the field bus or sensor feed.

M8: Typically 3–4 pins, used for compact sensors.

M12: offers 3 to 17 pins, available with types of coding (A, B, D, X, etc.) to indicate the application (for example, power, signal, Ethernet).

MIL-Spec connectors (for example, MIL-DTL-5015)

Developed for military and aerospace use, these connectors are robust and capable of handling high power and extreme environments. They are often used in transport, heavy equipment and plane.

Push-Pull Circular Connectors

Used in medical equipment, transmission and instrumentation. These connectors are valued by their compact size, rapid mating and safe connection. Lemo -style connectors are a well -known example, often used in surgical and test equipment.

Real world solutions using circular connectors

Circular connectors are not only theoretical components, but are solving real world problems in all industries:

Industrial automation

In smart factories, M12 connectors allow reliable connections between PLC, sensors, actuators and power supplies. Its blocking and sealed mechanism help reduce inactivity time due to vibration or pollution.

Medical devices

Pull-Pull circular connectors are favored in the diagnostic systems of image and hand monitors due to their sterilization and rapid disconnection in emergencies.

Transport

Trains, buses and electric vehicles use circular connectors to guarantee data and vibration -resistant data for signaling systems, load ports and control modules.

Outdoor surveillance

Surveillance cameras mounted in outdoor environments or at high altitude often depend on circular connectors with IP68 classification to maintain data connectivity and food under rain, powder and extreme temperatures.

https://www.ywconnectors.com/m12-connectors

How to work with manufacturers

Once you have reduced its specifications, it is essential to work directly with an authorized connector or distributor manufacturer. Here we show you how to optimize the process:

Application samples: The creation of early prototypes helps guarantee mechanical adjustment and electrical performance.

Search Customization: Some applications need modified contact arrangements, housing sizes or overload cable sets.

Evaluate quality systems: Choose suppliers that adhere to ISO or UL certifications to guarantee long -term reliability.

Verify delivery times: for high volume production, guarantee the availability of components and delivery consistency.

Conclusion

Choosing the correct circular connector may seem like a small detail in a larger design project, but can significantly affect performance, safety and maintenance. When carefully evaluating the electrical, environmental and mechanical requirements of its application, and by taking advantage of the wide range of circular connector solutions today, you can ensure that your system remains reliable and ready for the future.

Whether it is wired from an intelligent robot, designing medical diagnoses or building a next -generation vehicle, the circular connector is more than a plug: it is a cornerstone of modern connectivity.