Cuando trabaje con conectores industrialesSi desea piezas que funcionen bien en todo momento. A muchos clientes les resulta difícil elegir entre Conectores circulares M8 y M12. En este artículo, utilizaremos un Problema, agitación y solución para ayudarle a comprender las diferencias. Le mostraremos cómo YWun importante fabricante chino de conectores, hace grandes conectores circulares, conectores D Suby conectores personalizados que satisfagan sus necesidades.

1. Introducción

Conectores circulares se utilizan en muchos sectores, como la automatización, la robótica y las energías renovables. Ayudan a unir cables y los protegen del polvo, el agua y las vibraciones. Pero muchos usuarios finales se enfrentan a un problema cuando no están seguros de qué conector es el adecuado para sus necesidades técnicas. Se preguntan: "¿Debo elegir el compacto Conector M8 o el más robusto Conector M12?"

En YW fabricamos conectores de alta calidad y contamos con años de experiencia en la producción de conectores circulares y muchos otros tipos de conectores. Siga leyendo para saber cómo nuestros productos pueden resuelva sus problemas y por qué nuestros puntos fuertes en fabricación son una gran ventaja para usted.

2. El problema

Problema: confusión a la hora de elegir el conector adecuado

Elegir entre Conectores circulares M8 y M12 puede ser un gran problema para muchas empresas. He aquí una breve lista de problemas a los que se enfrentan los clientes:

- No conocer las diferencias clave: Muchos desconocen la diferencia de tamaño, potencia y uso entre un conector M8 y uno M12.

- Problemas de compatibilidad técnica: A los clientes les preocupa si el conector se adapta a su sistema. Quieren saber capacidad actual, valores de tensióny configuraciones de clavijas.

- Coste frente a rendimiento: Algunos no están seguros de si un conector de menor coste como el M8 funcionará bien o si el Conector M12 muchas características son necesarias en condiciones duras.

- Fiabilidad en entornos difíciles: En industrias con altas vibraciones, exposición a productos químicos o inmersión en agua, existe la preocupación de que el conector índices de fracaso.

Estas preguntas y preocupaciones pueden ralentizar el proyecto y añadir costes adicionales si se cometen errores.

3. Agitar: Por qué estos problemas se agravan

Agitar: El impacto en su operación

Puede ser muy molesto cuando se utiliza el conector equivocado. Veamos lo que ocurre:

- Tiempo de inactividad por rendimiento: Si utiliza un conector incorrecto, su sistema puede fallar. Esto puede provocar paradas de la máquina y tiempos de inactividad. Fíjese en los datos de tasa de fallos de estudios reales. Por ejemplo, en entornos de alta vibración, Conectores M8 tienen una tasa de fracaso del 28% al cabo de un año. Por el contrario, Conectores M12 muestran sólo una tasa de fallos del 7%. Esta diferencia es enorme si se tienen en cuenta los costes de inactividad.

- Aumento de los costes de mantenimiento: Imagínese gastar más tiempo en reparaciones debido a que los conectores se desgastan más rápido. En Conector M8 puede darle sólo 100-150 ciclos de apareamiento mientras que el Conector M12 pueden ofrecer más de 500 ciclos. Los ciclos de acoplamiento bajos dan lugar a más sustituciones, más mano de obra y más dinero gastado en mantenimiento.

- Compatibilidad deficiente: Si su conector no se ajusta a las necesidades de su sistema (por ejemplo, requisitos de corriente y tensión, configuraciones de patillas específicas necesarias), su sistema puede ser poco fiable. Por ejemplo, Conectores M8 son adecuados para sensores que utilizan 30-60V mientras que Conectores M12 soportan de 250 a 630 V y muchos pines. Esto es especialmente cierto en sistemas en red como los que utilizan Ethernet industrial (codificación M12 D).

- Uso limitado en entornos agresivos: El clima, los productos químicos y el agua pueden llevar a los conectores más allá de sus límites nominales. Con tasas de fallo como las que se observan en nuestras tablas de datos, una mala coincidencia en la clasificación medioambiental puede provocar costosos tiempos de inactividad. Los clientes de los sectores de la alimentación, la automoción o las energías renovables no pueden permitirse estos contratiempos.

Estos retos le demuestran que elegir el conector equivocado puede ser un grave error. Es importante hacer la elección correcta basándose en datos técnicos detallados y en un rendimiento demostrado.

4. Los datos: Diferencias numéricas clave

A continuación se presentan una serie de cuadros que muestran las claras diferencias entre Conectores circulares M8 y M12. Estas cifras proceden de importantes fuentes de datos como Harting, Contacto en Phoenixy estudios de mercado de Investigación de Grand View.

Tabla 1: Especificaciones técnicas

| Característica | Conector M8 | Conector M12 |

|---|---|---|

| Diámetro de la rosca | 8 mm | 12 mm |

| Capacidad actual | Hasta 4A | Hasta 12A (codificación S: 16A @ 630V) |

| Tensión nominal | 30-60V | 250-630V (con codificación S) |

| Configuraciones de clavijas | 3/4/5 patillas | 4/5/8/12/17-pin |

| Clasificación IP | IP67/IP68/IP69K | IP67/IP68/IP69K |

| Ciclos de apareamiento | 100-150 ciclos | Más de 500 ciclos (modelos blindados) |

| Tipos de codificación | Codificación A (sensores) | Codificación A/B/D/S/T (Ethernet, alimentación, bus de campo) |

| Peso | 10-15g | 25-50g |

Cuadro 2: Casos de aplicación

| Industria | M8 Uso dominante | M12 Uso dominante |

|---|---|---|

| Robótica | Sensores conjuntos | Señales de potencia y control del motor |

| Automoción | Pequeños sensores en sistemas ABS y neumáticos | Gestión de baterías y recarga de vehículos eléctricos |

| Procesado de alimentos | Sensores resistentes al lavado (IP69K) | Transportadores y PLC de alta resistencia |

| Energías renovables | Microsensores para paneles solares | Conexiones del motor del aerogenerador |

| Centros de datos | - | Ethernet de alta velocidad (codificación D, Cat6A) |

Cuadro 3: Adopción y tendencias del mercado

| Métrica | Conector M8 | Conector M12 |

|---|---|---|

| Cuota de mercado (2023) | 32% | 68% |

| Tasa de crecimiento (2023-30) | 6,8% CAGR | 12.1% CAGR |

| La mayor demanda del sector | Dispositivos médicos, HVAC | Automatización de fábricas, IIoT |

| Precios | $5-15 por unidad | $10-40 por unidad |

| Demanda híbrida | Bajo (un solo uso) | Alta (combos de potencia + datos) |

Cuadro 4: Análisis de la tasa de fallos

| Medio ambiente | Tasa de fallos M8 | Tasa de fallos M12 |

|---|---|---|

| Alta vibración | 28% (después de 1 año) | 7% (después de 1 año) |

| Exposición química | 15% | 5% |

| Inmersión en agua | 12% (con grado de protección IP68) | 3% (con grado de protección IP68) |

Estos cuadros muestran cómo Conectores M12 suelen proporcionar más potencia, mayor durabilidad y mejor rendimiento en condiciones duras. También demuestran que Conectores M8 son una buena opción para aplicaciones pequeñas y de bajo consumo, como los sensores.

5. Ventajas de trabajar con la Juventud Obrera

En YWentendemos todos los problemas a los que se enfrenta a la hora de elegir el conector adecuado para su máquina o sistema. Así es como resuelva sus problemas:

Nuestros puntos fuertes en fabricación

- Producción de alta calidad: Aplicamos normas estrictas como CEI 61076-2-101 para diseñar y fabricar nuestros conectores. Esto significa que siempre obtendrá piezas fiables y seguras.

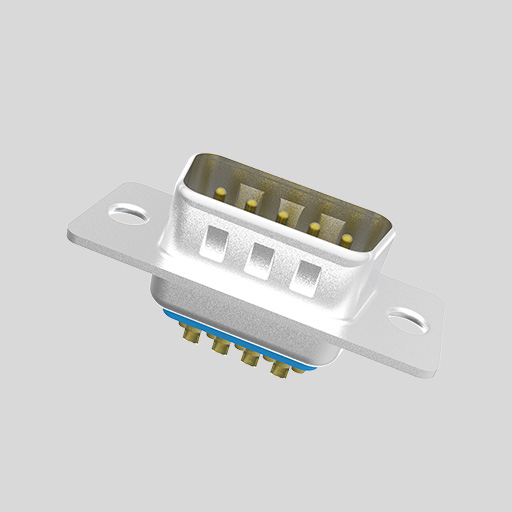

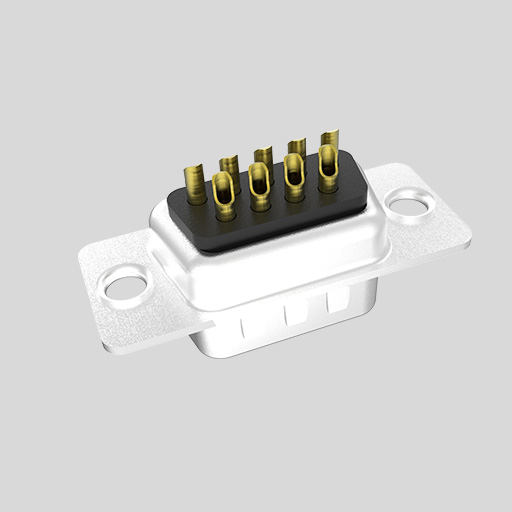

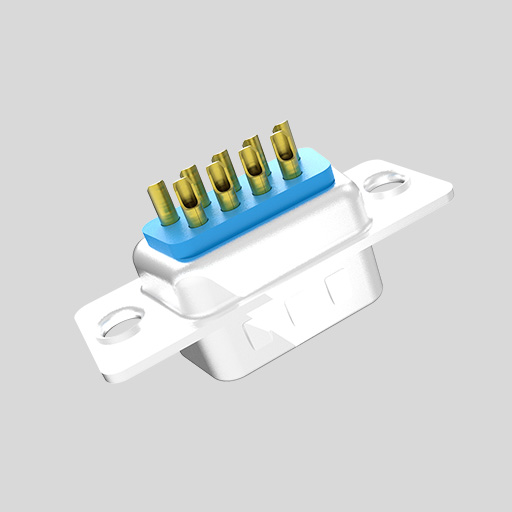

- Amplia gama de productos: Producimos tanto conectores circulares y D Conectores secundarios. Consulte nuestra gama completa de conectores circulares para más detalles. También ofrecemos conectores personalizados que satisfagan sus necesidades específicas.

- Opciones de codificación innovadoras: Nuestros conectores utilizan muchos tipos de codificación como Codificación A, B, D, S y T. Esto los hace excelentes para diversas funciones, entre ellas sensores, Ethernet industrialy bus de campo aplicaciones (por ejemplo PROFIBUS).

- Precios competitivos: Nuestros productos ofrecen un gran valor. Puede estar seguro de que obtendrá un rendimiento de calidad a un precio justo.

- Soluciones a medida: Porque entendemos que cada proyecto tiene necesidades únicas, ofrecemos soluciones de conectores personalizadas. Esta flexibilidad permite satisfacer con precisión sus necesidades de diseño.

- Fiabilidad duradera: Con más de 500 ciclos de acoplamiento disponibles en algunos de nuestros Conectores M12obtendrá un producto duradero. Disfrute de menos tiempo de inactividad y más tiempo de actividad con nuestros fiables conectores.

6. Casos prácticos y ejemplos reales

Veamos algunas historias de nuestros clientes. Estos ejemplos muestran cómo nuestros conectores ayudan a resolver problemas reales.

Caso práctico 1: Robótica y automatización

Se necesita una empresa de robótica sensores que pudiera funcionar en un espacio reducido. Eligieron nuestro Conectores M8 debido a su poco peso (10-15 g) y a su pequeño 8 mm de diámetro de rosca. Estos conectores encajan perfectamente en los espacios reducidos de los robots.

- Resultado:

- Alta precisión del sensor

- Sin tiempo de inactividad

- Menor coste de mantenimiento

Caso práctico 2: Ethernet industrial en centros de datos

Una fábrica inteligente necesitaba enviar tanto energía como datos a través del mismo conector. Necesitaban un conector que soportara altas velocidades. Eligieron nuestro Conectores M12 con Codificación D.

- Resultado:

- Comunicación Ethernet fiable

- Alta capacidad de corriente, hasta 12 A (incluso 16 A con codificación S)

- Menos errores y menos sustituciones de cables

Para más información sobre soluciones de red de alto rendimiento, consulte nuestra página sobre D Conectores secundarios.

Caso práctico 3: Aplicaciones de energías renovables

Un fabricante de aerogeneradores necesitaba conectores capaces de soportar altas vibraciones y condiciones meteorológicas adversas. Su elección fue el Conector M12 gracias a su robusta construcción y a sus más de 500 ciclos de acoplamiento. Con solo una tasa de fallos de 7% en entornos de altas vibraciones, consiguieron reducir los costes de mantenimiento y una producción de energía más eficiente.

- Resultado:

- Mayor durabilidad en condiciones duras

- Menor índice de averías y reparaciones

- Mayor ciclo de vida gracias a sus conexiones resistentes a la humedad y a los productos químicos

7. Por qué los conectores M12 están ganando terreno

Según un estudio de mercado de Grand View Research (2023)Aquí tienes algunos consejos:

- Crecimiento del mercado: Conectores M12 con una cuota de mercado de 68% y una tasa de crecimiento interanual anual del 12,1%. Conectores M8 32% de cuota y 6,8% de TACC.

- Gran demanda del sector: Industrias como la automatización de fábricas y la IIoT impulsan la demanda de Conectores M12. Son populares porque permiten transmisión de datos mediante tipos de codificación innovadores, como Codificación A/B/D/S/T.

- Fiabilidad mejorada: Como ha visto en los datos de la tasa de fallos, el Conectores M12 son mucho más fiables en altas vibraciones, químicos y sumergidos en agua.

Esta tendencia creciente demuestra que muchas empresas optan por Conectores M12 por su exigente rendimiento y durabilidad.

8. Lista de comprobación para elegir el conector adecuado

Antes de elegir el conector definitivo, aquí tienes un lista de control sencilla para ayudarte a decidir:

- Requisitos de corriente y tensión:

- Conectores M8: 30-60V, hasta 4A.

- Conectores M12: 250-630V, hasta 12A o incluso más con codificación S.

- Necesidades de configuración de pines:

- M8: 3, 4 ó 5 clavijas para sensores sencillos.

- M12: De 4 a 17 pines para satisfacer necesidades complejas de datos y alimentación.

- Condiciones ambientales:

- M8: Funciona bien en condiciones suaves y con pocas vibraciones.

- M12: Ideal para entornos difíciles, como fuertes vibraciones, exposición a productos químicos e inmersión en agua (consulte las clasificaciones IP: IP67/IP68/IP69K).

- Requisitos de instalación y mantenimiento:

- M8: Menor coste pero menores ciclos de acoplamiento (100-150).

- M12: Mayor coste pero con más de 500 ciclos de acoplamiento y mayor durabilidad.

- Caso práctico adecuado:

- M8: Ideal para aplicaciones pequeñas de bajo consumo (por ejemplo, sensores, iluminación LED).

- M12: Perfecto para aplicaciones de alta potencia, Ethernet industrial (codificación D) y alta velocidad.

Recuerde que elegir el conector adecuado puede ahorrarle tiempo, dinero y frustraciones. Nuestros expertos de YW siempre están aquí para ayudarle. Más información conectores personalizados para ver cómo podemos adaptar soluciones a su empresa.

9. Reflexiones finales

Elegir entre Conectores M8 y M12 no es fácil. La elección equivocada conlleva verdaderos problemas. Con la Conector M8obtendrá una solución compacta adecuada para sistemas de baja potencia. Si necesita conexiones fiables para máquinas robustas y que consumen mucha energía, el Conector M12 coincide mejor.

Utilización de la Problema, Agitación y Solución (PAS) te ayuda a verlo:

- En Problema es la confusión sobre qué conector se ajusta a tus necesidades.

- En Agitar es el aumento del tiempo de inactividad y de los costes derivados de una elección equivocada.

- En Solución es recurrir a un fabricante de confianza como YW que ofrece una gama de conectores fabricados para durar.

YW se enorgullece de ser uno de los principales fabricantes de conectores eléctricos de China. Producimos conectores conectores circulares, D Conectores secundariosy conectores personalizados que siguen normas exactas y cumplen sus requisitos más exigentes.

10. Más información y contacto

En YWNos preocupamos por nuestros clientes. Si tiene alguna pregunta o necesita ayuda para elegir el producto adecuado, póngase en contacto con nosotros. Puede consultar nuestras páginas detalladas de productos y obtener más información sobre nuestra amplia gama de soluciones. Aquí tiene algunos enlaces útiles:

- Conectores circulares de alta calidad - Explore nuestros conectores circulares líderes del sector.

- Conectores D Sub fiables - Vea cómo funcionan nuestros conectores D Sub en muchas aplicaciones.

- Soluciones a medida - Conozca nuestras opciones de conectores diseñados a medida.

Estamos aquí para ayudarle a elegir la mejor opción para sus necesidades industriales.

Eligiendo YW para sus necesidades de conectores, está dando un paso hacia una mayor fiabilidad y eficiencia. Nuestros productos están diseñados para ayudarle a superar retos, reducir el tiempo de inactividad y aumentar la productividad.

11. Contacto

Llámenos hoy mismo o visite nuestra sitio web para más detalles. Permítanos ayudarle a superar sus problemas de conectores con una solución inteligente que ahorra tiempo y dinero.

Fin del artículo