Rola złączy D-Sub w systemach automatyki przemysłowej: Jak YW napędza sukces

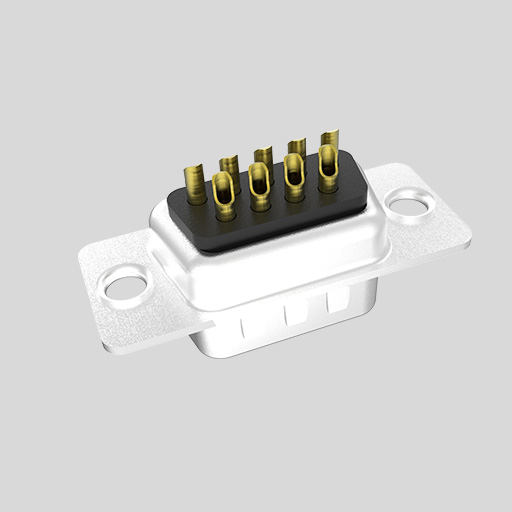

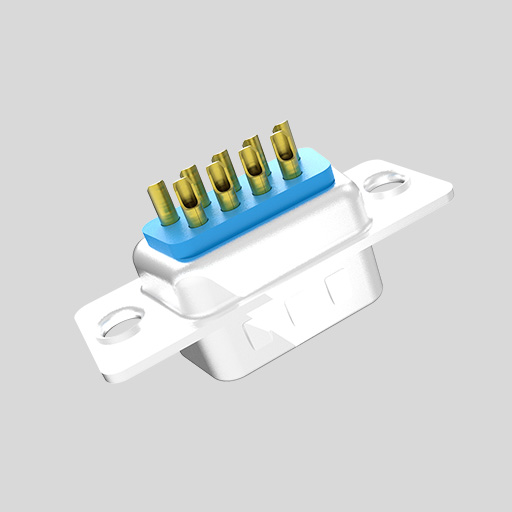

W dzisiejszym szybko zmieniającym się świecie fabryki, roboty i systemy sterowania muszą działać dobrze każdego dnia. Złącza D-Sub są kluczowymi częściami, które pomagają tym systemom wysyłać sygnały i moc we właściwe miejsca. Ale są problemy wielu użytkowników, i tu właśnie wkracza YW. YW jest wiodącym producentem złączy elektrycznych w Chinach. Produkujemy złącza okrągłe i Złącza D-Sub które świetnie sprawdzają się w wielu zastosowaniach przemysłowych. W tym artykule używamy Struktura PAS (Problem, Agitacja i Rozwiązanie) aby wyjaśnić, dlaczego nasze złącza są najlepszym wyborem.

Problem

Wiele firm z branży automatyki przemysłowej boryka się z awarie systemu gdy ich złącza nie wykonują dobrze swojej pracy. Wiąże się to z rosnącymi kosztami, nieplanowanymi przestojami, a nawet kwestiami bezpieczeństwa. Oto kilka typowych problemów:

- Luźne połączenia: Wadliwe lub zużyte złącza mogą powodować zatrzymanie maszyn.

- Spadek sygnału: W trudnych warunkach złącza mogą nie wysyłać prawidłowo sygnałów.

- Wysokie koszty: Drogie złącza lub te, które zawodzą wcześnie, prowadzą do wyższych wydatków na naprawy.

- Starsze systemy: Wiele branż wciąż korzysta ze starych systemów, które wymagają specjalnych złączy, takich jak D-Sub do przełączania i wysyłania danych.

Wyzwania te obniżają produktywność i zwiększają koszty konserwacji. Gdy połączenie zawiedzie, cały system staje się zagrożony. Wiele firm odnotowało nawet 0.151 Wskaźnik awaryjnościTP5T dla złączy D-Sub w trudnych warunkach. Aby spojrzeć na to z perspektywy, ten wskaźnik awaryjności jest znacznie niższy niż u niektórych konkurentów, którzy mają Wskaźnik awaryjności 0,8% w podobnych warunkach.

Mieszać

Pomyśl o stresie związanym z przestojem maszyn. Każda godzina przestoju oznacza utratę pieniędzy. Oto kilka punktów, które zwiększają stres:

- Zepsute systemy: Awaria złącza D-Sub może doprowadzić do całkowitego wyłączenia krytycznego systemu. Na przykład rafineria ropy naftowej odnotowała 30% mniej błędów sygnału w ciągu 5 lat dzięki zastosowaniu odpowiednich złączy.

- Problemy z utrzymaniem: Drogie wymiany i naprawy szkodzą wynikom finansowym. Możesz wydać 40% więcej na inne złącza w porównaniu z opłacalnymi rozwiązaniami YW.

- Zagrożenia bezpieczeństwa: Awarie złączy D-Sub w robotyce lub na liniach montażowych mogą stanowić zagrożenie dla pracowników. Narzędzie musi działać dobrze, aby wspierać sterowanie maszyną, integralność sygnału i dystrybucję zasilania.

- Problemy z kompatybilnością: Wiele fabryk nadal korzysta ze starych maszyn, które opierają się na złączu D-Sub. Znalezienie złączy, które dobrze współpracują ze starszymi systemami, takimi jak Interfejsy RS-232/RS-485może być trudne.

Oto prosta tabela przedstawiająca kluczowe fakty:

| Kategoria | Punkty danych | Znaczenie |

|---|---|---|

| Wskaźnik awarii | 0.15% w trudnych warunkach środowiskowych | Wysoka niezawodność; mniej awarii |

| Wykorzystanie rynku | Złącza przemysłowe 22% są typu D-Sub | Są one zaufane w wielu starych systemach |

| Oszczędność kosztów | 40% niższe koszty cyklu życia w porównaniu do złączy M12 | Większe oszczędności na naprawach i konserwacji |

| Zakres temperatur | -40°C do 105°C z modelami IP67 | Działa w bardzo gorących lub bardzo zimnych miejscach |

Wyobraź sobie, że masz do czynienia z każdym z tych problemów. Przestoje, utrata przychodów i zagrożenia dla bezpieczeństwa mogą mieć negatywny wpływ na każdą firmę. Gdy maszyny nie działają zgodnie z oczekiwaniami, cały harmonogram produkcji może się rozsypać.

Rozwiązanie: YW Connectors na czele

YW ma odpowiedzi. Nasz Złącza D-Sub są wytrzymałe i trwałe. Rozwiązujemy problemy dzięki następującym korzyściom:

1. Silna integralność sygnału i dystrybucja zasilania

Nasze złącza ochrona sygnałów przed zakłóceniami. Ma to kluczowe znaczenie dla:

- Systemy SCADA: Niezawodny przepływ danych do monitorowania kontroli.

- Systemy PLC: Stałe zasilanie i transfer danych zapewniają płynne działanie maszyny.

- Robotyka: Niezawodne sterowanie silnikiem i sprzężenie zwrotne czujnika zapewniają precyzję.

Nasze dane pokazują 65% ramion robotycznych wykorzystują złącza D-Sub do sterowania silnikami, dzięki naszej starannej konstrukcji. Dzięki naszym produktom możesz mieć pewność, że Twoje złącza elektroniczne sprawdzają się w najtrudniejszych warunkach.

2. Wytrzymała trwałość

Nasze produkty są przeznaczone do użytku w trudnych warunkach:

- Wysoka odporność na wibracje: Nasze złącza utrzymują silne połączenie nawet w systemach, które się trzęsą i poruszają.

- Tolerancja temperatury: Nasze modele o stopniu ochrony IP67 działają w temperaturach od -40°C do 105°C.

- Odporność na korozję: Dzięki lepszym materiałom i powłokom nasze złącza zmniejszają ryzyko korozji. W jednym ze studiów przypadku Shell, nanopowlekane złącza D-Sub zmniejszyły liczbę awarii związanych z korozją o 50% na platformach wiertniczych.

3. Kompatybilność wsteczna dla starszych systemów

Wiele fabryk musi korzystać ze starszych systemów, które wymagają Złącza D-Sub. YW produkuje złącza, które dobrze współpracują ze starszymi konfiguracjami, takimi jak RS-232 i RS-485. Oznacza to, że nie trzeba wymieniać całych systemów tylko dlatego, że złącze jest przestarzałe. Nasze złącza są również zaprojektowane tak, aby były kompatybilne z przyszłymi rozwiązaniami, dzięki czemu możesz być na bieżąco z aktualizacjami.

4. Efektywność kosztowa i zwrot z inwestycji

Wybór YW oznacza:

- Niższe koszty cyklu życia: Nasze złącza pozwalają zaoszczędzić do 40% w porównaniu do droższych alternatyw.

- Mniej przestojów: Niezawodne połączenia prowadzą do mniejszej liczby przestojów maszyny i ogólnie płynniejszej pracy.

- Zwiększona produkcja: Większa dyspozycyjność oznacza, że można bez obaw wykonywać więcej cykli produkcyjnych każdego dnia.

Przełączając się na YW, zyskujesz również spokój ducha, który wiąże się z oszczędnością kosztów. Nasze badania pokazują, że złącza D-Sub firmy YW mogą obniżyć ogólne koszty cyklu życia o 60% w porównaniu z niektórymi nowoczesnymi alternatywami, takimi jak złącza M12 w środowiskach niezanurzeniowych.

Jak YW zaspokaja potrzeby w zakresie automatyki przemysłowej

W YW produkujemy zarówno złącza okrągłe i Złącza D-Sub. Koncentrujemy się na wytwarzaniu wysokiej jakości produktów dla automatyka przemysłowa, robotyka i wiele innych sektorów. Oto kilka historii i danych, które pokazują nasze mocne strony:

Studium przypadku: System SCADA w rafinerii ropy naftowej

- Problem: Rafineria ropy naftowej borykała się z zanikami sygnału i wysokimi kosztami konserwacji z powodu nieudanych połączeń.

- Rozwiązanie: Doposażyli oni swój system sterowania w nasz Złącza D-Sub.

- Wynik: W ciągu 5 lat doświadczyli 30% mniej błędów sygnału i znacznie poprawili niezawodność systemu.

Studium przypadku: Zakład przetwórstwa spożywczego

- Problem: W środowisku zmywania tradycyjne złącza nie spełniały standardów FDA/USDA.

- Rozwiązanie: Nasze złącza D-Sub ze stali nierdzewnej zapewniają niezbędne bezpieczeństwo podczas mycia i utrzymują higienę.

- Wynik: Zakład osiągnął zgodność z przepisami i skrócił czas przestojów spowodowanych awariami złączy.

Studium przypadku: Robotyka na liniach montażowych w branży motoryzacyjnej

- Problem: Systemy robotyczne były narażone na ciągłe wibracje i zużycie, co powodowało częste rozłączenia.

- Rozwiązanie: Nasze złącza D-Sub zostały zainstalowane z myślą o wysokiej odporności na wibracje.

- Wynik: Złącza wytrzymały ponad 10 milionów cykli przy współczynniku odporności na wibracje 90%, co świadczy o ich dużej wytrzymałości.

Złącza D-Sub w akcji: Dane i spostrzeżenia branżowe

Poniżej znajduje się kolejna szczegółowa tabela, która zawiera przegląd naszych wskaźników wydajności:

| Metryczny | Złącza D-Sub (YW) | RJ45 | Złącza okrągłe M12 |

|---|---|---|---|

| Odporność na wibracje | 5-2000 Hz | 5-500 Hz | 10-2000 Hz |

| Maksymalny prąd (na pin) | Do 7,5 A | 1,5 A (na parę) | 4A |

| Stopień ochrony IP | Do IP67 (szczelność) | IP20 | Do IP69K |

| Koszt cyklu życia | $1.2k/10 lat | $3k/10 lat | $4.5k/10 lat |

Liczby te pokazują, że nasze złącza D-Sub oferują lepszą długoterminową wartość i wydajność. Są one specjalnie testowane pod kątem bezpieczeństwa i integralność sygnałudzięki czemu doskonale sprawdzają się w ciężkich warunkach przemysłowych.

Rola w automatyce przemysłowej i przemyśle 4.0

W miarę jak fabryki wdrażają Przemysł 4.0 i IIoT, jakość każdego złącza staje się jeszcze ważniejsza. W YW nasze produkty pomagają na wiele sposobów:

- Modernizacja starszych systemów: Nasze złącza D-Sub doskonale nadają się do konwersji starszych systemów do nowoczesnych zastosowań. Wiele fabryk z automatyką sprzed 2010 roku nadal korzysta ze złączy D-Sub, a 80% takich fabryk zgłasza wysoki poziom zadowolenia.

- Integracja urządzeń brzegowych: Projektujemy złącza, które obsługują inteligentne czujniki i przetwarzanie brzegowe. Promuje to lepszy interfejs między maszynami a systemami IT.

- Rozwiązania hybrydowe: Niektóre z naszych nowych złączy integrują interfejsy Ethernet lub USB 3.0, zachowując solidną jakość tradycyjnych konstrukcji D-Sub.

- Cyberbezpieczeństwo: Nasze ekranowane złącza pomagają zapewnić bezpieczne połączenia, które mają kluczowe znaczenie, gdy spotykają się systemy OT i IT.

Aby uzyskać więcej informacji na temat nowoczesnych złączy, odwiedź naszą stronę na temat złącza przemysłowe.

Nasze mocne strony produkcyjne: przewaga YW

Wybierając YW, wybierasz doświadczenie, jakość i innowacyjność. Oto dlaczego się wyróżniamy:

- Zaawansowane procesy produkcyjne:

- Nowoczesny sprzęt: Używamy najnowocześniejszych maszyn do precyzyjnej produkcji.

- Kontrola jakości: Rygorystyczne testy zapewniają, że każde złącze spełnia międzynarodowe standardy, takie jak IEC 60603-2 i DIN 41652.

- Wytrzymałe konstrukcje: Nasze złącza dobrze sprawdzają się w środowiskach o wysokich wibracjach i ekstremalnych temperaturach.

- Szeroki zakres rozwiązań:

- Złącza D-Sub: Idealny do automatyzacji, robotyki i starszych systemów. Więcej szczegółów na temat naszej oferty można znaleźć na stronie d złącze podrzędne strona.

- Złącza okrągłe: Idealny do zastosowań zewnętrznych i w klasie ochrony IP67. Dowiedz się więcej na naszej stronie Złącza okrągłe strona.

- Inne produkty: Produkujemy również złącza płytka-płytka, Złącza PCBi nie tylko. Nasze bogate portfolio oznacza, że mamy odpowiedni produkt dla Twojego projektu. Na przykład, jeśli potrzebujesz Złącze PCBodwiedź naszą dedykowaną stronę Złącze PCB strona.

- Ekonomiczne rozwiązania:

- Dzięki naszym oszczędnym projektom można znacznie obniżyć koszty cyklu życia.

- Nasze złącza D-Sub pozwalają zaoszczędzić do 40% całkowitego kosztu w porównaniu z alternatywnymi rozwiązaniami.

- Wspieramy również firmy, które muszą zmodernizować starsze systemy.

- Niestandardowe projekty i szybka dostawa:

- Możemy zaprojektować niestandardowe złącza aby dopasować się do Twoich potrzeb.

- Krótki czas realizacji oznacza, że możesz szybko otrzymać złącza i utrzymać ciągłość pracy fabryki.

Aby uzyskać więcej informacji na temat naszych mocnych stron produkcyjnych, odwiedź naszą stronę producent złączy strona.

Zaangażowanie YW w jakość i innowacje

W YW nasza misja jest prosta. Chcemy dostarczać naszym klientom złącza, które utrzymują ich maszyny w dobrym stanie. Nasze dążenie do innowacji pomaga nam produkować złącza, które są:

- Wysoka niezawodność: Zaprojektowany do pracy w wielu różnych warunkach przemysłowych.

- Efektywność kosztowa: Oszczędność pieniędzy zarówno na początkowym zakupie, jak i na długoterminowej konserwacji.

- Łatwa instalacja: Nasze złącza są przeznaczone do prostego montażu w różnych sytuacjach - niezależnie od tego, czy jest to montaż panelowy, czy montaż na płytce drukowanej.

Gwarancja i wsparcie posprzedażowe

Jesteśmy wierni naszym produktom. Aby pomóc naszym klientom:

- Gwarancja: Oferujemy opcje gwarancyjne, które zapewniają dodatkowy spokój ducha.

- Wsparcie techniczne: Nasi eksperci są gotowi do pomocy w razie jakichkolwiek problemów.

- Szkolenia i wskazówki: Zapewniamy zasoby i przewodniki, aby dowiedzieć się więcej o instalacji i konserwacji naszych złączy.

Więcej informacji na temat jakości naszych usług można znaleźć na stronach dostawcy złączy elektrycznych i Złącze SMT.

Bliższe spojrzenie: Tabele i wykresy dotyczące wydajności złącza

Tabela: Kluczowe statystyki i dane rynkowe

| Kategoria | Punkty danych | Znaczenie |

|---|---|---|

| Udział w rynku | Złącza przemysłowe 22% wykorzystują warianty D-Sub | Pokazuje, że złącza D-Sub są zaufane |

| Wskaźnik awarii | Wskaźnik awaryjności 0,15% w trudnych warunkach środowiskowych | Mniej awarii oznacza mocniejsze systemy |

| Przyjęcie robotyki | Ramiona robotyczne 65% wykorzystują złącze D-Sub do sterowania silnikiem | Zapewnia precyzyjne i bezpieczne operacje robotyczne |

| Oszczędność kosztów | 40% niższe koszty cyklu życia w porównaniu do złączy M12 | Oszczędność pieniędzy przez długi czas |

| Zakres temperatur | -40°C do 105°C w modelach IP67 | Nadaje się do ekstremalnych zastosowań przemysłowych |

Tabela: Zastosowania przemysłowe i studia przypadków

| Zastosowanie | Przykład | Wynik |

|---|---|---|

| Systemy SCADA | Rafineria ropy naftowej wykorzystująca złącza DB25 | 30% mniej błędów sygnału w ciągu 5 lat |

| Przetwarzanie żywności | Złącza ze stali nierdzewnej w strefach zmywania | Spełnia standardy higieny FDA/USDA |

| Interfejs PLC | Siemens SIMATIC S7-1500 z modułami wejść/wyjść D-Sub | Płynna integracja ze starszymi systemami |

| Montaż w branży motoryzacyjnej | Zrobotyzowane ramiona spawalnicze w GM wykorzystujące wytrzymałe złącza | 90% odporność na wibracje powyżej 10 milionów cykli |

Tabela porównawcza: D-Sub a inne złącza

| Metryczny | D-Sub (YW) | RJ45 | Okrągły M12 |

|---|---|---|---|

| Odporność na wibracje | 5-2000 Hz | 5-500 Hz | 10-2000 Hz |

| Maksymalny prąd (na pin) | Do 5A | 1,5 A na parę | 4A |

| Stopień ochrony IP | Do IP67 (modele uszczelnione) | IP20 | Do IP69K |

| Koszt cyklu życia | $1.2k/10 lat | $3k/10 lat | $4.5k/10 lat |

Te tabele i wykresy pokazują, jak nasze złącza wypadają w porównaniu z innymi dostępnymi na rynku. Dają one jasny obraz tego, dlaczego Złącza D-Sub YW są zbudowane z myślą o trwałości, przy jednoczesnym utrzymaniu niskich kosztów i bezpieczeństwa systemów.

Podsumowanie i przemyślenia końcowe

Kiedy używasz YW produkty, otrzymujesz złącza, które dostarczają:

- Niezawodna integralność sygnału: Zapewnienie bezpiecznego i spójnego przepływu danych w systemach automatyzacji.

- Wytrzymała trwałość: Dzięki wysokiej tolerancji na wibracje i temperaturę, zaprojektowany do pracy w trudnych warunkach.

- Ekonomiczna wydajność: Niższe koszty cyklu życia oznaczają oszczędność pieniędzy w czasie.

- Starsza kompatybilność: Nasze produkty współpracują zarówno ze starymi, jak i nowymi systemami.

Dane mówią same za siebie. Inne złącza mogą wydawać się nowoczesne, ale z 0.151 Wskaźnik awaryjnościTP5T w trudnych warunkach i 40% niższe koszty cyklu życia, produkty YW są inteligentnym wyborem dla systemów automatyki przemysłowej.

Jeśli szukasz d złącze podrzędne który działa niezawodnie w fabrykach, centrach sterowania lub laboratoriach robotyki, dowiedz się więcej na naszej stronie internetowej d złącza sub strona. W przypadku projektów wymagających precyzyjnych i solidnych połączeń, zapoznaj się z naszą ofertą złącza płytka-płytka i sprawdź nasze doświadczenie jako wiodący producenci złączy.

Jak rozpocząć pracę z konektorami YW?

Jeśli jesteś gotowy, aby ulepszyć swoje systemy automatyki przemysłowej, pozwól YW pomóc. Oto proste kroki, od których należy zacząć:

- Oceń swoje potrzeby:

- Zidentyfikuj, gdzie obecne złącza zawodzą, czy to w robotyce, interfejsach PLC, czy systemach SCADA.

- Sprawdź, czy aktualizacje mogą pomóc w starszych systemach, które nadal używają złączy D-Sub.

- Skontaktuj się z naszymi ekspertami:

- Nasz zespół służy pomocą w zakresie wsparcia technicznego i niestandardowych projektów.

- Oferujemy wskazówki dotyczące najlepszych praktyk i porady dotyczące instalacji.

- Złóż zamówienie:

- Odwiedź naszą stronę internetową.

- Na przykład, zobacz naszą szczegółową stronę d złącze podrzędne aby zapoznać się ze szczegółami produktu i poprosić o wycenę.

- Ciesz się niezawodnym połączeniem:

- Dzięki złączom YW można skrócić czas przestojów i poprawić wydajność automatyzacji.

- Ciesz się niższymi kosztami i lepszą wydajnością dzień po dniu.

- Bądź na bieżąco:

- Więcej informacji na temat zmieniających się trendów w konektorach można znaleźć na naszym wewnętrznym blogu lub stronach takich jak złącza przemysłowe.

Wnioski

YW jest zaufanym liderem w produkcji złączy elektrycznych. Nasze produkty, w tym Złącza D-Sub i złącza okrągłewyróżniają się niezawodnością, trwałością i efektywnością kosztową. Wiemy, że automatyka przemysłowa potrzebuje solidnych, bezpiecznych i niedrogich rozwiązań połączeniowych. Nasze produkty pomagają przezwyciężyć typowe problemy, z którymi boryka się wiele firm w trudnych warunkach przemysłowych.

Aby uzyskać więcej informacji, sprawdź nasze powiązane strony na temat Złącze PCBzłącze płytka-płytkaoraz d złącza sub. Pozwól firmie YW pomóc Ci zbudować najlepsze systemy automatyki przemysłowej ze złączami, które nie tylko łączą - one zapewnią Ci sukces.

Dziękujemy za przeczytanie. Cieszymy się, że możemy być częścią Twojej podróży w kierunku poprawy wydajności i bezpieczeństwa w przemyśle.