Mastering Wire Connections: The Ultimate Guide to Choosing and Using Wire Connectors in Manufacturing (O guia definitivo para escolher e usar conectores de fios na manufatura)

Este artigo fornece um guia abrangente para entender e utilizar conectores de fios em várias configurações de fabricação. Nós nos aprofundamos nas especificidades da seleção, aplicação e práticas recomendadas de conectores em setores como industrial, médico, militar, telecomunicações, robôs industriais e automação. Seja você um engenheiro, técnico ou especialista em compras, este guia oferece insights valiosos, melhorando sua compreensão e ajudando-o a tomar decisões informadas.

Índice

Por que os conectores de fios são essenciais na fabricação?

Os conectores de fios são componentes fundamentais em qualquer sistema elétrico. Eles fornecem um método seguro e confiável para unir fios, criar circuitos seguros e garantir o fluxo eficiente de eletricidade. Na manufatura, a confiabilidade de cada conexão é primordial, pois um único ponto de falha pode levar a um tempo de inatividade dispendioso, danos ao equipamento ou até mesmo riscos à segurança. Selecionados e instalados adequadamente conectores de fios garantem um desempenho consistente, resistem a fatores ambientais e facilitam a manutenção e as modificações.

Imagine uma linha de montagem automatizada complexa em que centenas de sensores, atuadores e sistemas de controle precisam se comunicar perfeitamente. Conectores de fios desempenham o papel crucial de garantir que todos os componentes estejam interconectados corretamente, permitindo uma operação tranquila e evitando interrupções. Sua importância vai além da simples funcionalidade; eles contribuem para a segurança geral, a eficiência e a longevidade dos processos de fabricação.

Que tipos de conectores de fios são comumente usados?

Uma ampla variedade de conectores de fios Existem vários tipos de cabos, cada um projetado para aplicações e tipos de fios específicos. Alguns dos mais comuns incluem:

- Conectores de crimpagem: Esses conectores usam deformação mecânica (crimpagem) para prender um fio em uma luva de metal. Conectores de crimpagem fornecem uma conexão forte e estanque ao gás, ideal para aplicações em que a vibração ou o movimento são uma preocupação. O processo é rápido e dá bons resultados.

- Conectores de deslocamento de isolamento (IDCs): Os IDCs perfuram o isolamento de um fio para fazer contato com o condutor. São comumente usados em telecomunicações e aplicações de baixa tensão.

- Terminais de parafuso: Esses conectores usar um parafuso para prender em um fio, criando uma conexão segura conexão. Terminais de parafuso são versáteis e permitem a fácil conexão e desconexão dos fios.

- Conectores push-in (também chamados de conectores Wago): Conectores push-in permitem uma operação rápida e sem ferramentas fio inserção. Os grampos com mola prendem a fio, fornecendo um serviço confiável conexão.

- Conectores soldados: A solda oferece uma ligação permanente e altamente condutiva entre um fio e um conector. Conectores de solda são ideais para aplicações que exigem máxima confiabilidade e resistência a fatores ambientais.

| Tipo de conector | Vantagens | Desvantagens | Aplicativos comuns |

|---|---|---|---|

| Conectores de crimpagem | Conexão forte e estanque ao gás, resistente a vibrações | Requer ferramenta de crimpagem, não é facilmente reutilizável | Automotivo, maquinário industrial, aeroespacial |

| Deslocamento do isolamento | Rápido e fácil de usar, sem necessidade de decapagem de fios | Limitado a tipos específicos de fios, não adequado para aplicações de alta corrente | Telecomunicações, eletrônicos de baixa tensão |

| Terminais de parafuso | Versátil, reutilizável, fácil de conectar e desconectar | Pode se soltar com o tempo devido à vibração, exigindo uma chave de fenda | Painéis elétricos, sistemas de controle, fiação geral |

| Conectores push-in | Muito rápido e fácil de usar, sem ferramentas | Pode não ser adequado para todos os tipos de fios ou ambientes de alta vibração | Iluminação, fiação de edifícios, caixas de junção |

| Conectores soldados | Excelente condutividade, conexão permanente, resistente a fatores ambientais | Requer habilidade e equipamento de solda, não sendo facilmente reutilizável | Aplicações de alta confiabilidade, eletrônicos sensíveis, aplicações militares e aeroespaciais |

Como escolher o conector de fio certo para sua aplicação

Escolhendo o caminho certo conector de fio envolve a consideração de vários fatores críticos:

- Tipo e tamanho do fio: O conector deve ser compatível com o do fio bitola (diâmetro) e tipo (com fio ou sólido). Usar o cabo errado tamanho conector pode resultar em uma conexão ou danos ao fio.

- Requisitos de corrente e tensão: O conector deve ser classificado para a corrente e a tensão máximas que fluirão através do circuito.

- Condições ambientais: Considere fatores como temperatura, umidade, vibração e exposição a produtos químicos. Escolha um conector projetado para suportar o ambiente específico.

- Requisitos de inscrição: Pense em fatores como a necessidade de conexões e desconexões, a importância de alívio de tensão, e quaisquer restrições de espaço.

- Padrões do setor: O conector deve atender aos padrões de seu setor.

Ao avaliar cuidadosamente esses fatores, você pode selecionar um conector de fio que garante um sistema confiável e duradouro conexão. Por exemplo, um robô industrial que opera em um ambiente hostil com alta vibração provavelmente exigiria um sistema robusto de conectores de crimpagem projetados para condições extremas. Por outro lado, um aplicativo de telecomunicações pode utilizar IDCs por sua facilidade de instalação e adequação a sinais de baixa tensão.

Aplicações específicas em ambientes industriais

Na fabricação industrial, conectores de fios são amplamente utilizados em painéis de controle, máquinas, sistemas de distribuição de energia e muito mais. É importante usar o tipo correto.[^3] Por exemplo, máquinas para serviços pesados geralmente exigem conectores com altas classificações de corrente e construção robusta para suportar as exigentes cargas elétricas e vibrações.

- Conector de reboque com furo industrial fêmea oferece conexões duráveis e resistentes a intempéries, essenciais para máquinas expostas a ambientes adversos.

- Nos painéis de controle, terminais de parafuso e conectores push-in são comumente usados para facilitar a conexão organizada e segura de vários fios, simplificando a solução de problemas e a manutenção.

Conectores no setor de dispositivos médicos

O setor de dispositivos médicos exige os mais altos padrões de confiabilidade e segurança. Conectores de fios usados em equipamentos médicos devem atender a requisitos rigorosos de biocompatibilidade, compatibilidade de esterilização e desempenho elétrico. Conectores de solda são frequentemente preferidos em aplicações críticas devido à sua condutividade superior e resistência à corrosão.

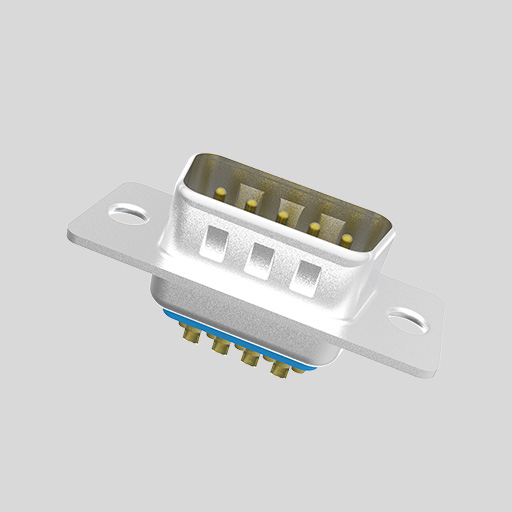

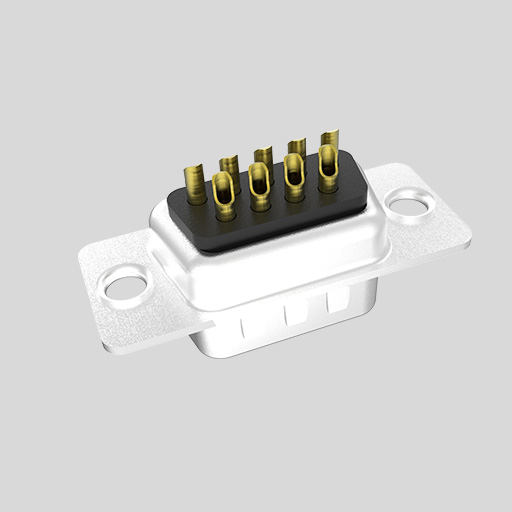

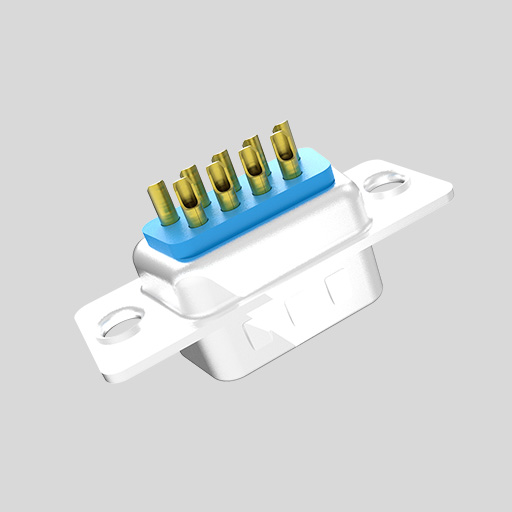

Conector D-sub de alta qualidade são frequentemente empregados em dispositivos médicos para transmissão de dados e sinais, garantindo a integridade de informações vitais. Esses conectores são projetados para minimizar a interferência e manter a qualidade do sinal, o que é fundamental para o diagnóstico e o tratamento precisos.

Conectores de nível militar: Atendendo a exigências rigorosas

Os aplicativos militares exigem conectores que podem suportar temperaturas extremas, choques, vibrações e exposição a produtos químicos agressivos e interferência eletromagnética (EMI). De nível militar conectores são construídos de acordo com especificações rigorosas, garantindo um desempenho confiável nos ambientes mais exigentes.

Esses conectores frequentemente apresentam projetos especializados, como conectores circulares com mecanismos de travamento robustos e blindagem EMI. [Eles são usados em uma ampla gama de equipamentos militares, de sistemas de comunicação a sistemas de armas, onde a falha não é uma opção.

Telecomunicações: Garantindo a transmissão confiável de sinais

Em telecomunicações, conectores de fios desempenham um papel fundamental na manutenção da integridade dos sinais de dados e voz. Os IDCs são amplamente usados para conectar telefones e redes cabos, fornecendo um serviço rápido e confiável conexão sem a necessidade de decapagem de fios.

- Conectores din U-229 de 6 pinos com plugue e soquete são exemplos de conectores usado em equipamentos de telecomunicações especializados, oferecendo conexões seguras e confiáveis para vários tipos de sinais. O foco em telecomunicações é minimizar a perda de sinal e a interferência, garantindo uma comunicação clara e consistente.

Conectores de fios para robôs industriais e automação

Os robôs industriais e os sistemas de automação dependem muito de conectores de fios para interconectar sensores, atuadores, controladores e fontes de energia. Conectores de crimpagem são frequentemente preferidos por sua resistência à vibração e segurança conexão, garantindo uma operação confiável em ambientes dinâmicos.

Conector reto direito de metal para sensor à prova d'água M8O [^6] fornece uma solução compacta e robusta para conectar sensores e atuadores em braços robóticos e outras máquinas automatizadas, oferecendo proteção contra poeira e umidade. A confiabilidade desses conectores é fundamental para manter a precisão e a eficiência dos processos automatizados.

Práticas recomendadas para instalação e manutenção

A instalação e a manutenção adequadas são essenciais para garantir a confiabilidade de longo prazo do conectores de fios. Aqui estão algumas das principais práticas recomendadas:

- Use as ferramentas corretas: Sempre use as ferramentas recomendadas para crimpagem, decapagem e instalação conectores.

- Preparação adequada do fio: Faixa o fio isolamento com o comprimento correto, garantindo que não haja danos ao condutor. Para fio trançado, torção os fios juntos antes de inseri-los no conector.

- Conexões seguras: Certifique-se de que o fio esteja totalmente inserido no conector e que todos os parafusos ou grampos estejam devidamente apertados.

- Alívio da tensão: Fornecer alívio de tensão para o cabo para evitar estresse no conexão.

- Inspeção regular: Inspecione periodicamente conectores para detectar sinais de desgaste, corrosão ou danos. Substitua qualquer conectores imediatamente.

Solução de problemas comuns de conectores de crimpagem

Mesmo com a instalação adequada, conector de fio Às vezes, podem surgir problemas. Aqui estão alguns problemas comuns e como solucioná-los:

- Conexão solta: Se um conexão se sente solto ou intermitente, verifique se o fio esteja totalmente inserido e que todos os parafusos ou grampos estejam devidamente apertados.

- Corrosão: A corrosão pode levar ao aumento da resistência e à perda de sinal. Limpe qualquer conectores ou substituí-los, se necessário.

- Superaquecimento: O superaquecimento pode indicar uma má conexão ou um circuito. Verifique o fio e conector e garantir que sejam apropriados para a aplicação.

- Fio quebrado: Se um fio pausas no conexão pode indicar estresse ou vibração excessiva. Termine novamente o fio com um novo conector e fornecer alívio de tensão.

Perguntas frequentes

Qual é o melhor tipo de conector para aplicações de alta vibração?

Conectores de crimpagem são, em geral, a melhor opção para aplicações de alta vibração devido à sua robustez, à prova de gás conexão.

Posso reutilizar os conectores de fios?

Alguns conectores, como terminais de parafuso, são reutilizáveis. No entanto, conectores de crimpagem e os IDCs normalmente não são projetados para reutilização.

Como posso saber qual tamanho de conector de fio devo usar?

O conector deve ser compatível com a bitola (diâmetro) do fio. Consulte a seção conector especificações do fabricante para orientação.

Qual é a diferença entre fio trançado e fio sólido?

Fio trançado é composto de vários fios menores de arame, enquanto o sólido fio é um condutor único e sólido. Fio trançado é mais flexível, enquanto o sólido fio é melhor para aplicativos em que o fio não será movido com frequência.

Como posso contatá-los para necessidades específicas de conectores de fios?

Como um fabricante especializado em conectores para vários setores, convidamos você a entrar em contato conosco pelo nosso site ou por telefone para discutir suas necessidades específicas. Temos a experiência necessária para adaptar soluções que se alinham perfeitamente às necessidades de seu projeto, independentemente de sua complexidade ou especialização.

Resumo

- Conectores de fios são componentes essenciais na fabricação, garantindo a confiabilidade da energia elétrica conexões.

- Diferentes tipos de conectores são adequados para diferentes aplicações e fio tipos.

- Escolhendo o caminho certo conector envolve a consideração de fatores como fio tipo, requisitos de corrente e tensão, condições ambientais e requisitos de aplicação.

- A instalação e a manutenção adequadas são essenciais para garantir a confiabilidade de longo prazo do conectores de fios.

- Solução de problemas comuns conector de fio Os problemas envolvem a verificação de conexões, corrosão, superaquecimento e fios quebrados.

- Como fabricante de conectores de fios, estamos prontos para ajudá-lo. Entre em contato conosco para descobrir como nossos produtos e nossa experiência podem elevar seus projetos. Seu sucesso é nossa prioridade. 1. Os conectores de fios são essenciais. 2. A crimpagem é rápida. 3. O tipo correto é crucial. 4. Os conectores D-sub garantem a integridade dos dados. 5. Conectores circulares com travamento são comuns. 6. Os conectores M8 são robustos.