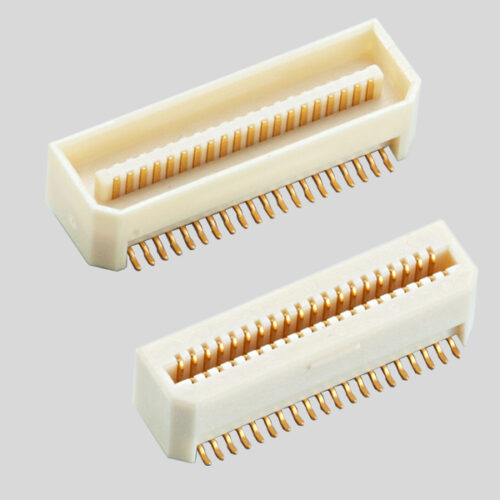

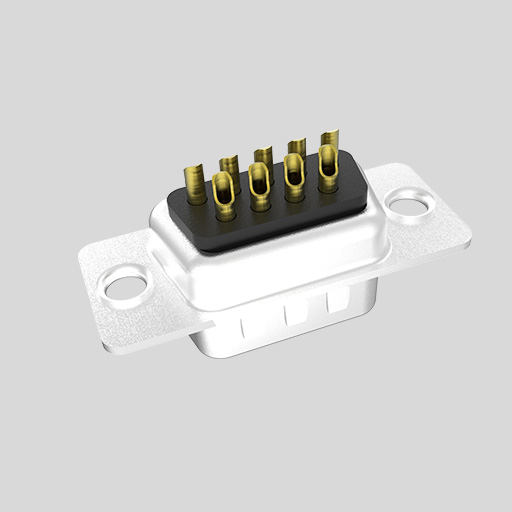

OEM/ODM & custom designs

YW professional R&D engineers support rapid custom design within 2-4days and DFM within 1 week to meet your unique connector requirements without delays.

Fast Sales Response

You will get our quick response and instant meeting participation availability. We ensure fast communication and efficient service to keep your project moving forward.

Quality inspection & testing

Committed to Quality, Driven by Precision and Reliability. All connectors are manufactured under our strict quality control standards, ensuring high performance and stability.