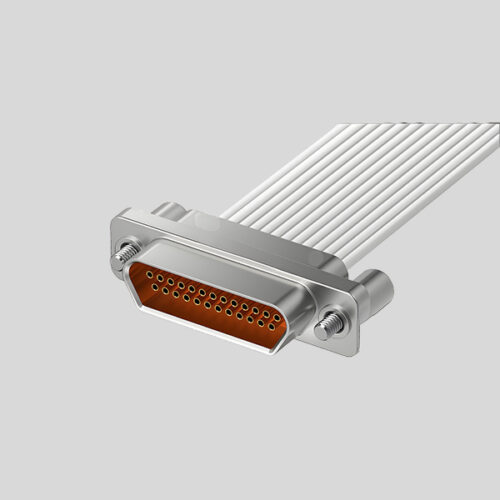

25 pin micro d sub connector Custom Micro-D Cable Assembly Factory in China MIL-DTL-83513

25 pin micro d sub connector Custom Micro-D Cable Assembly Factory in China MIL-DTL-83513

Pitch: 1.27mm

Number of Contacts: 25 Pin

Mounting Type: Soldering Type

Shell Material: Aluminum Alloy

Plating: Gold plated contacts, Nickel plated shell

Current Rating: 3A

Operating Temperature: -55°C to +125°C

25 pin micro d sub connector Custom Micro-D Cable Assembly Factory in China MIL-DTL-83513

YW Precision Electronics offers a wide range of standard and custom D-Sub connectors in both vertical and right angle, soldering and crimping.

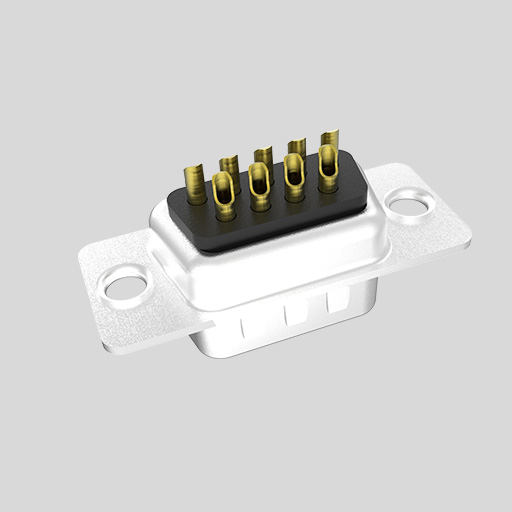

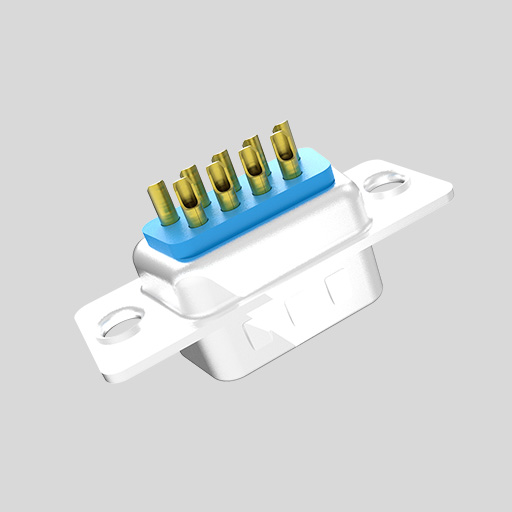

Our high-performance 21 pin micro d connector is engineered for precision and reliability in space-constrained applications.

Applications for 25 pin micro d sub connector

Aerospace avionics (high-density I/O in flight control, navigation, sensors, data acquisition)

Space & satellites (payload electronics, telemetry, compact interconnects in constrained enclosures)

Defense & tactical systems (rugged communications, mission computers, portable equipment harnessing)

UAV / drones (lightweight, high-pin-count connections for cameras, gimbals, GPS/IMU modules)

Robotics & automation (servo/encoder signal interfaces, compact control box wiring, feedback loops)

Medical devices (diagnostic instruments, imaging subsystems, patient monitoring modules, portable devices)

Industrial equipment & instrumentation (measurement modules, controllers, sensors, industrial PCs)

Test & measurement (signal routing, compact interface panels, lab/field data logging systems)

Telecom & networking equipment (embedded modules, backplane/box interconnects, compact I/O)

Motorsport & high-performance vehicles (data logging, telemetry, ECU interfaces where space/weight matter)

Marine / offshore electronics (navigation and control systems requiring reliable, vibration-resistant interconnects)

Micro-D / Micro-D-Sub Connectors FAQ

1) What is a Micro-D (Micro-D-Sub) connector?

A Micro-D connector—often written as Micro-D-Sub connector or micro d sub connector—is a compact, high-density D-subminiature style connector,

commonly using 1.27mm pitch contacts. It’s widely used where space and weight are critical while maintaining reliable signal transmission.

2) Is “Micro-D connector” the same as “Micro-D-Sub connector”?

In most sourcing scenarios, Micro-D connector and Micro-D-Sub connector refer to the same product family. Buyers may use both terms interchangeably (micro d / micro-d / micro d sub). What matters most is confirming the pin count, pitch, mounting type, contact plating, and mating interface.

3) Which pin counts do you offer (9/15/21/25/31/51 pin Micro-D)?

We support a range of pin counts for Micro-D / Micro-D-Sub connectors. Common options include 9, 15, 21, 25, 31, 51 contacts (and additional configurations depending on series). If you tell us your required pin number and mating connector, we can recommend the best match.

4) Do you provide PCB mount Micro-D connectors (straight / right-angle)?

Yes. Micro-D / Micro-D-Sub connectors are available in different PCB mounting styles, such as:

Through-hole or SMT (depending on series)

Straight (vertical) or right-angle

Share your board constraints (height, keep-out area, assembly process) and we’ll confirm a suitable footprint and drawing.

5) Do you offer Micro-D cable assemblies?

Yes. We can supply Micro-D cable assemblies (micro-d cable connector + cable) based on your wiring requirements, including:

Cable length, wire gauge, shielding, jacket material

Pin assignment / wiring diagram

Overmold or backshell/strain relief solutions (depending on design)

Send your pinout or application notes and we’ll propose a build.

6) What plating options are available for Micro-D-Sub contacts?

Common contact plating options include gold plating (for stable low contact resistance) and other plating specifications based on cost and application requirements. If you have a target standard or thickness requirement, share it and we’ll align the plating spec accordingly.

7) Can you support shielding (EMI) options for Micro-D connectors?

Depending on the series and housing design, shielding solutions may be available to help with EMI control. If your system is noise-sensitive, let us know your environment (industrial, aerospace, medical, telecom) and the mating configuration so we can recommend the best approach.

8) Are your Micro-D / Micro-D-Sub connectors compatible with standard Micro-D mating interfaces?

Micro-D is a standardized form factor, but compatibility depends on exact series geometry, hardware, and contact arrangement. To avoid mismatch, please share:

The mating connector brand/series (if known)

Drawing, part number, or photos

We’ll verify inter-mate compatibility before sampling.

9) What is the difference between Micro-D and standard D-Sub connectors?

A standard D-Sub (DB/DE/DA series) is larger and typically uses a wider pitch and bigger shell. A Micro-D (Micro-D-Sub) connector is smaller and higher-density,

commonly used when space, weight, and compact routing are priorities.

10) What electrical and mechanical performance should I confirm before ordering?

For Micro-D / Micro-D-Sub connectors, key items to confirm include:

Current rating, voltage rating, insulation resistance

Contact resistance and durability targets

Operating temperature range

Vibration/shock needs and retention method

If you share your application environment and requirements, we’ll recommend a suitable series and test plan.

11) What is the mating cycle / durability of your Micro-D connectors?

Mating cycles vary by design, plating, and application. We can provide durability guidance based on the specific Micro-D / Micro-D-Sub series you select. If your application requires higher cycle life, we’ll recommend an appropriate contact plating and design approach.

12) Can you provide samples, drawings, and datasheets?

Yes. We can provide:

Samples for evaluation

2D drawings / 3D files (if available for your model)

Datasheet/spec sheet

Tell us your target pin count and mounting style, and we’ll arrange the right documentation set.

13) What is your MOQ and lead time for Micro-D / Micro-D-Sub connectors?

MOQ and lead time depend on configuration (pin count, plating, hardware, custom cable assembly).

We typically support prototype sampling and scalable production. Share your estimated annual usage and project timeline for an accurate quote.

14) Can you customize Micro-D connectors for my project?

Yes. For qualified projects we can support customization such as:

Cable length and wiring (for cable assemblies)

Contact plating spec alignment

Packaging/labeling

Minor mechanical adaptation (case-by-case)

Send your drawing/pinout and we’ll evaluate feasibility quickly.

15) How do I request a quote for a 25-pin Micro-D-Sub connector (or other pin count)?

To quote accurately, please provide:

Pin count (e.g., 25 pin micro d sub connector)

Mounting type (PCB / cable, straight / right-angle)

Plating requirement (if specified)

Qty (sample + forecast)

Mating connector info or drawing/photo

We’ll reply with the recommended part and quotation.

Contact us to get a quote for 1.27mm 25 pin micro d sub connector. Email: [email protected]