Introduction

In the medical field, precision, safety, and durability are paramount. Medical devices demand reliable interconnect solutions that can perform under rigorous conditions. Circular connectors play an indispensable role in connecting and powering critical equipment, such as diagnostic machines, patient monitoring systems, imaging devices, and surgical instruments. As technological advancements continue to reshape healthcare, circular connectors, especially M8 and M12 connectors, offer robust performance in compact, efficient designs. This article explores their significance in medical applications, focusing on their features, benefits, and why they remain a top choice.

1. The Importance of Reliability in Medical Equipment

Medical equipment must work flawlessly. A minor failure can lead to serious consequences. Connectors are vital for ensuring electrical and signal continuity. Circular connectors offer stable, secure connections, ensuring seamless communication and power delivery. Their design resists vibration, moisture, and mechanical stress, making them suitable for hospital environments.

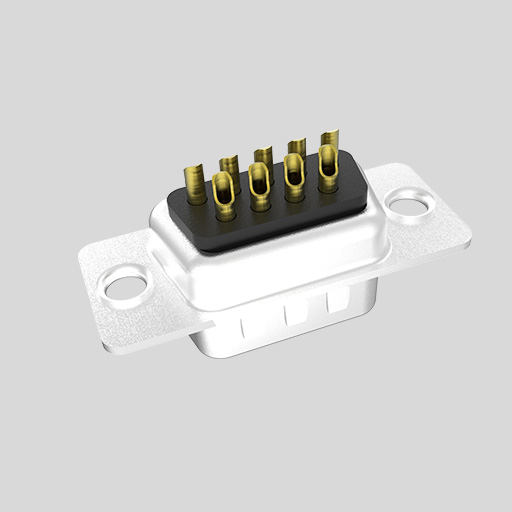

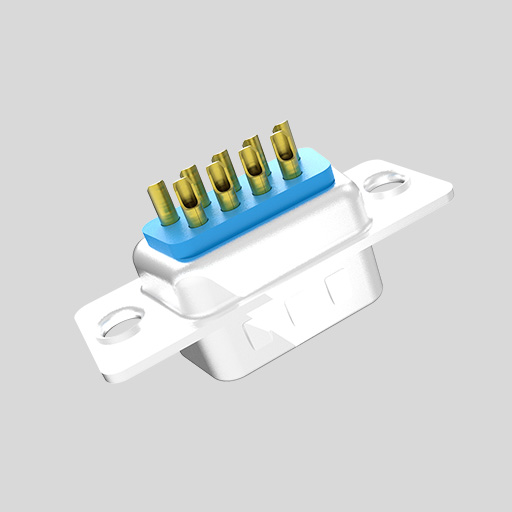

2. What Are Circular Connectors?

Circular connectors are cylindrical, multi-pin interconnect devices used for power and signal transmission. Their shape allows for high pin density in a compact footprint. These connectors come in various sizes and configurations, including M8 and M12 connectors, which are common in compact, high-performance devices. They often include locking mechanisms for secure mating and are built with materials that ensure electrical insulation and mechanical strength.

3. Applications in Medical Equipment

Circular connectors are widely used in:

- Patient Monitoring Systems: Reliable transmission of real-time data from sensors to displays.

- Imaging Devices (CT, MRI): High data throughput in EMI-sensitive environments.

- Surgical Instruments: Durability and sterility are critical for connectors in operating rooms.

- Diagnostic Machines: Connectors provide consistent signals for accurate diagnostics.

- Rehabilitation Devices: Compact and rugged connectors support mobility and long-term use.

4. Benefits of Using Circular Connectors

- Compact Design: Ideal for space-constrained medical devices.

- Durability: Withstand repeated use, sterilization, and harsh cleaning agents.

- Secure Locking: Prevent accidental disconnection.

- EMI/RFI Protection: Reduce electromagnetic interference.

- Ease of Use: Quick installation and maintenance.

5. M8 Connectors in Medical Equipment

The M8 connector is small yet powerful. Commonly used in sensors and actuators, it excels in patient monitoring and handheld diagnostic tools. Its compact size fits tight spaces, while the locking system ensures reliability.

Key advantages:

- Ideal for sensor connections

- Shielded against interference

- Resistant to moisture and cleaning agents

- Lightweight, easy to handle

6. M12 Connectors in Medical Equipment

M12 connectors offer more pins and higher current-carrying capacity than M8. They are used in more complex systems, such as imaging equipment and robotic surgical systems. M12 connectors support data protocols like Ethernet, making them ideal for high-speed data transfer.

Benefits include:

- High signal integrity

- Compatibility with industrial protocols

- Rugged housing for mechanical and environmental protection

- Vibration-resistant locking mechanism

7. Material Considerations for Medical Environments

Medical-grade connectors must resist cleaning chemicals, temperature changes, and corrosion. Many circular connectors use:

- Stainless steel shells: Corrosion resistance

- Gold-plated contacts: Reliable conductivity

- Silicone gaskets: Excellent sealing and flexibility

8. Regulatory Compliance and Standards

Medical connectors must comply with standards such as:

- ISO 13485: Quality management for medical devices

- IEC 60601: Safety and performance of medical electrical equipment

- RoHS and REACH: Environmental regulations

Circular connectors that meet these standards ensure device safety and patient protection.

9. Customization for Specific Medical Applications

Circular connectors can be customized with:

- Unique pin configurations

- Overmolded cables

- Custom colors for easy identification

- Sterilizable materials

These features enhance usability and integration with OEM equipment.

10. Why Choose YW for Circular Connectors

YW offers expertise in developing high-quality circular connectors tailored for medical applications. Our connectors meet global standards and are trusted by medical OEMs worldwide.

Key strengths:

- In-house R\&D for innovative designs

- Strict quality control for reliability

- Competitive pricing

- Custom solutions to meet exact specifications

- Fast delivery and responsive service

Whether it’s M8, M12, or custom circular connectors, YW ensures performance, safety, and value.

Conclusion

Circular connectors are essential in ensuring the reliability and performance of modern medical equipment. Their robust design, ease of use, and adaptability make them the preferred choice for manufacturers. M8 and M12 connectors, in particular, address the space, data, and durability demands of the healthcare sector. As medical devices continue to evolve, YW remains committed to providing advanced, reliable, and customized connector solutions for the industry’s future.