Introduction to circular connectors

Circular connectors play a fundamental role in aerospace and defense industries, providing essential electrical connections in some of the most demanding environments. These specialized interconnection solutions are designed to comply with strict military specifications while offering reliable performance in extreme conditions. Modern circular connectors, including M8 and M12 varieties widely used, offer robust solutions for signal transmission, power supply and data communications in critical mission applications.

M8 and M12 connector specifications

M8 connectors have an 8 mm lock thread and are commonly used in compact applications where space is limited. In general, they come with several pine configurations and can handle specific electrical requirements. M8 connectors include device connectors with LITZ cables for front or rear assembly, and use standard threads such as m8 x 0.5 or m8 x 1 fixing threads. These connectors are also available with welding connections for permanent facilities.

The M12 connector, with its 12 mm lock thread, is mainly used in factory automation applications, but has found extensive use in aerospace systems. These connectors are specifically designed to withstand washing and corrosive environments, which makes them ideal for aerospace applications. M12 connectors offer versatility with configurations of 3, 4, 5, 8 or 12 pin to accommodate several connection requirements. Erni M12 connectors adhere to IEC 61076-2 standards and are compatible with almost all field bus specifications.

M8 and M12 connectors are part of an integral range of metric circular connectors that also include other sizes such as M5, M10.5, M20 and M23. These connectors can be implemented with several assembly options and are compatible with conventional welding processes, which helps achieve significant savings in equipment manufacturing.

Aerospace and Defense Applications

Circular connectors have become indispensable components in aerospace and defense applications due to their reliability and performance characteristics. The main manufacturers such as connectivity offer you an integral portfolio of circular products that cover a thousand specified applications, spatial qualified, aerospace commercials, QPL and Cots. These connectors must meet strict requirements for weight reduction, improved size and performance minimization.

The thousand Deutsch circular connectors are particularly notable in the aerospace and defense sectors, since they continually drive the technology limits through the development of products that address the growing demands of smaller weight, lower size and higher performance. These connectors are also used in other demanding industries such as marine, oil and gas, and Autosport.

Advanced solutions and innovations

The aerospace industry requires interconnection solutions that can support extreme environmental conditions while maintaining signal integrity. Military and defense aerospace interconnection solutions often include Mil-DTL-38999, Supernine®, Series 806 and M28840 qualified circular connectors. These specialized connectors ensure reliable performance in critical mission systems.

Companies such as Conesys, an ISO 9001: 2015 and AS9100: 2016 certificate provider offer vertically integrated solutions that include filter connectors and transitory protection, circular specification connectors, a thousand specification, fiber optic terminis and specialized cable sets designed specifically for aerospace applications. These advanced solutions address the unique challenges faced by aerospace environments.

Future trends and developments

The future of circular connectors in aerospace and defense seems promising, with continuous innovations focused on greater miniaturization, greater durability and data transmission improvements. The 2025 CMSE conference and exposure will have more than 30 technical presentations on the design, reliability and application of electronic components for both terrestrial applications in plane, aerospace and military, as well as commercial and civil uses.

As aerospace systems become more and more complex and data intensive, circular connectors will continue to evolve to meet these changing requirements. It is expected that the industry’s trend towards the lighter, more compact and higher performance connector solutions, drives innovation in materials, design and manufacturing processes.

Conclusion

Circular connectors, particularly M8 and M12 varieties, represent essential components in aerospace and defense industries. Its robust design, reliability in hard environments and versatility are made ideal for critical applications where the failure is not an option. As aerospace and defense technologies continue to advance, circular connectors will remain at the forefront of interconnection solutions, allowing the next generation of aircraft, spacecraft and defense systems to function safely and efficiently in the most challenging conditions.

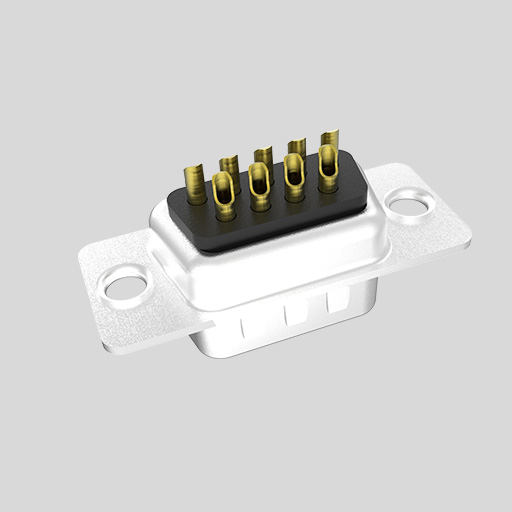

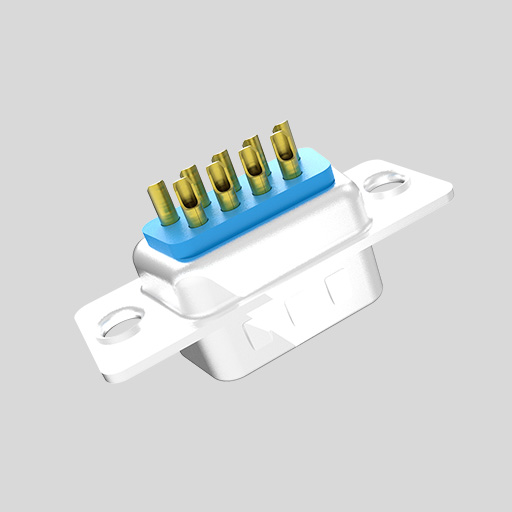

YW is a leading and trusted connector manufacturer in China, producing various circular connectors and d sub connectors for you.