Are you having trouble picking the right connector? Selecting the wrong board-to-board connector can lead to big headaches. Your project can face delays, extra costs, and even total failure.

Think about this: One wrong connector choice can cost you $4,000 to $32,000 in PCB redesigns and new tooling. Your device might fail in the field. Your customers might get upset. And your reputation could suffer.

But there’s good news! YW Connectors has the solution. We help engineers pick the perfect connector every time. Our step-by-step guide will save you time, money, and stress.

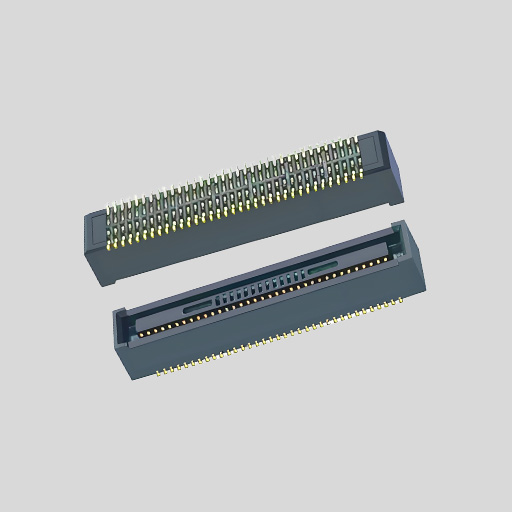

1. First, Look at Your Physical Needs

Before you buy any PCB connector, you must know what size you need.

Pitch Size: The First Big Choice

Pitch size means how far apart the pins are. This is very important.

| Where Used | Common Pitch Sizes | Best For |

|---|---|---|

| Small devices | 0.4mm – 0.8mm | Phones, wearables |

| Work machines | 0.8mm – 2.54mm | Factory tools, cars |

| Fast data | 0.35mm – 0.5mm | Computers, servers |

Too small? Your factory might not be able to make it. Too big? Your device gets too large.

YW Connectors offers 0.4mm board-to-board connectors that work in the smallest devices.

Stack Height: How Tall?

Stack height is how far apart your boards will be.

You can put boards:

- Side by side (coplanar)

- One over the other (mezzanine)

- At a right angle

Watch out! If boards bend, they can break the connectors. YW connectors have better mating height tolerance (±0.1mm) than many others to help with this problem.

Current and Voltage Needs

How much power will your connector carry?

| Use | Current per Pin | Voltage |

|---|---|---|

| Small gadgets | 0.5A – 1A | 50V – 100V |

| Work machines | 2A – 5A | 250V – 500V |

| Signal boards | 0.3A – 1A | 50V – 100V |

Remember: Hot places make connectors carry less power! At 105°C, your connector might only work at half power.

2. Match Your Electrical Needs

Mixing Power and Signals

Some connectors need to carry both power and data. This can be tricky.

The problem: Power pins can make noise that hurts signal pins.

The solution: YW Connectors makes special mixed-use connectors with:

- Separated ground pins

- Special shielding

- Power and signal areas kept apart

Fast Data Needs Special Care

For very fast data (5 Gbps or faster), you need:

- Signal timing within 0.25 nanoseconds

- Steady impedance (resistance)

- Good shielding from noise

Our SMT connectors are made for high-speed data with gold contacts that stay reliable over time.

Contact Material Matters

Gold contacts:

- Best for low voltage

- Works great at high temps

- Lasts longer (up to 95% rating at 125°C)

Tin contacts:

- Costs less

- Good for higher power

- Less reliable in hot places (loses 15% power for every 20°C over 85°C)

3. Will It Last in Your Environment?

Temperature Range

Where will your device work?

- Regular places: 0°C to 85°C

- Cars: -40°C to 105°C

- Extreme places: -55°C to 125°C

Big problem: 34% of connector failures come from fretting corrosion when temperatures change.

YW solution: We use gold flash plating on contact points to stop corrosion.

Shaking and Bumps

Connectors that shake loose cause big problems. This makes up 19% of field failures!

Our industrial connectors are tested to:

- 15G vibration

- Multiple shock tests

- Long-term shake tests (≥15 hours)

Water and Dust

Need to keep water out? We offer connectors with:

- IP67 seals for full water protection

- Special plastics that resist chemicals

- Self-aligning guides that work even when dirty

4. Making It Easy to Build

Solder Type Matters

There are three main ways to attach connectors:

- SMT (surface mount) – best for small, fast machines

- THT (through-hole) – strongest connection

- Press-fit – no solder needed, good for high voltage

Did you know? Press-fit connectors have 63% fewer defects than soldered ones for high-voltage use!

Fixing Board Stress

When boards flex, connectors can break. This causes 28% of field failures.

YW Connectors uses:

- Strain relief pads (≥0.2mm fillet)

- Floating contacts that move slightly

- Board stiffeners for extra support

Easy Assembly

No one wants hard-to-use connectors. We make ours with:

- Self-aligning guides (±0.1mm wiggle room)

- Clear marks for pin 1

- Polarized shapes so they only fit one way

5. Special Industry Needs

Different jobs need different connectors.

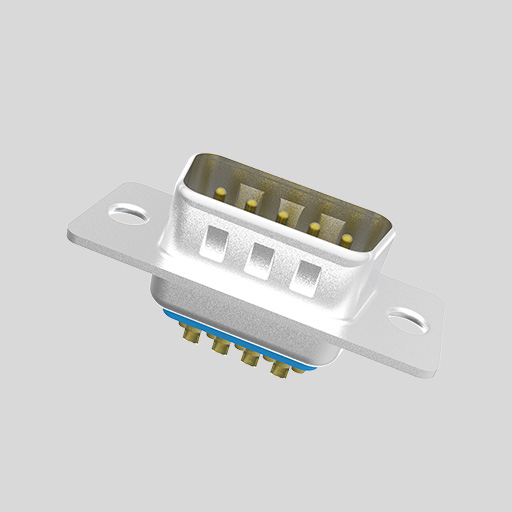

Car Connectors

Cars need the toughest connectors because they face:

- Big temperature changes (-40°C to 125°C)

- Constant vibration

- Long life (10+ years)

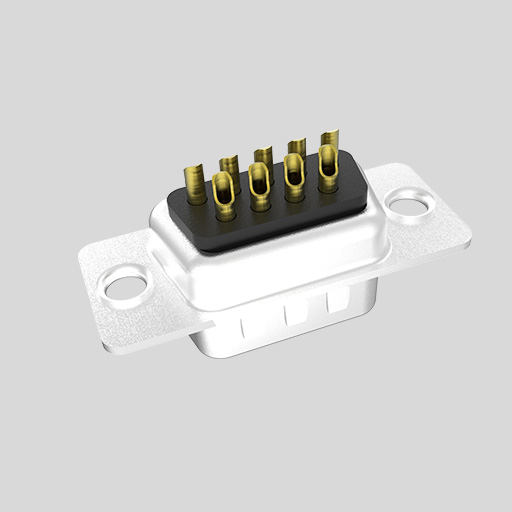

Medical Devices

Medical tools need:

- Materials that can be sterilized

- Low gas release

- Ultra-reliable contacts

- Clean room assembly

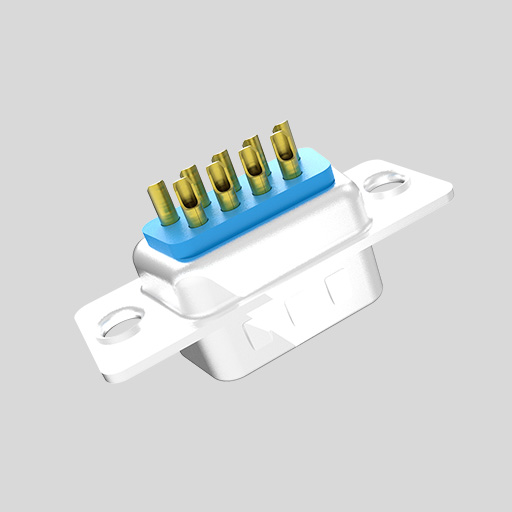

Consumer Electronics

Phones and gadgets need:

- Tiny size (often 0.4mm pitch)

- Low cost

- High-speed data

- Thin profile

6. Supply Chain Planning

Will You Get Stuck?

Big risk: Many connectors get discontinued within just a few years!

| Market | % Discontinued in 3 Years |

|---|---|

| Consumer | 72% |

| Industrial | 38% |

| Cars | 18% |

| Aerospace | 6% |

YW Connectors keeps making parts longer and offers second sources for critical connectors.

Lead Times

Custom connectors can take 12-30 weeks to make. But YW keeps popular types in stock to ship fast.

7. Decision Checklist

Use this simple checklist to find your perfect connector:

- [ ] Pitch size matches my space needs

- [ ] Current rating is enough (with 20% extra)

- [ ] Mating cycles more than I’ll need

- [ ] Temperature range covers my use case

- [ ] Vibration rating meets my environment

- [ ] IP rating for water/dust if needed

- [ ] Assembly method works with my factory

- [ ] Gold contacts for critical signals

- [ ] Available from stock to avoid delays

Why Choose YW Connectors?

At YW Connectors, we solve the three biggest connector problems:

- Reliability Issues – Our connectors last longer with better materials and testing

- Supply Problems – We keep stock ready and make parts consistently

- Technical Support – Our engineers help you choose the right connector the first time

As a leading connector manufacturer, we make over 30,000 types of electronic connectors for all uses.

Real-World Success Stories

Case Study: Indistrial Customer

A car parts maker was having 19% failure rate with their old connectors.

Our solution: We provided self-aligning board-to-board PCB connectors with floating contacts.

Result: Failures dropped to less than 1%, saving over $150,000 in warranty costs.

Case Study: Medical Device

A medical scanner maker needed ultra-reliable connectors that could handle 500+ mating cycles.

Our solution: Gold-plated high-cycle connectors with special strain relief.

Result: Zero field failures after 18 months and 7,500 units.

Common Connector Mistakes

- Under-specifying current – Always add 20% extra capacity

- Ignoring temperature – Hot environments need derating

- Forgetting testing – Test before full production

- Choosing price only – Cheap connectors cost more in failures

- Missing alignment features – Self-aligning saves assembly costs

Make the Right Choice Today

Picking the right connector shouldn’t be hard. Let YW Connectors help.

We offer:

- Free technical support

- Sample programs

- Fast delivery

- Custom designs

- Reliability testing

Don’t risk your project with the wrong connector. Contact YW Connectors today for help choosing the right board-to-board connector for your application.

Key Takeaways

- Match physical specs first – pitch, stack height, and pin count

- Check electrical needs – current, voltage and signal speed

- Consider the environment – temperature, vibration, water

- Plan for manufacturing – solder type, assembly method

- Think about long-term supply – second sources, lead times

With YW Connectors, you get the right part, right away, every time.